Leave Your Message

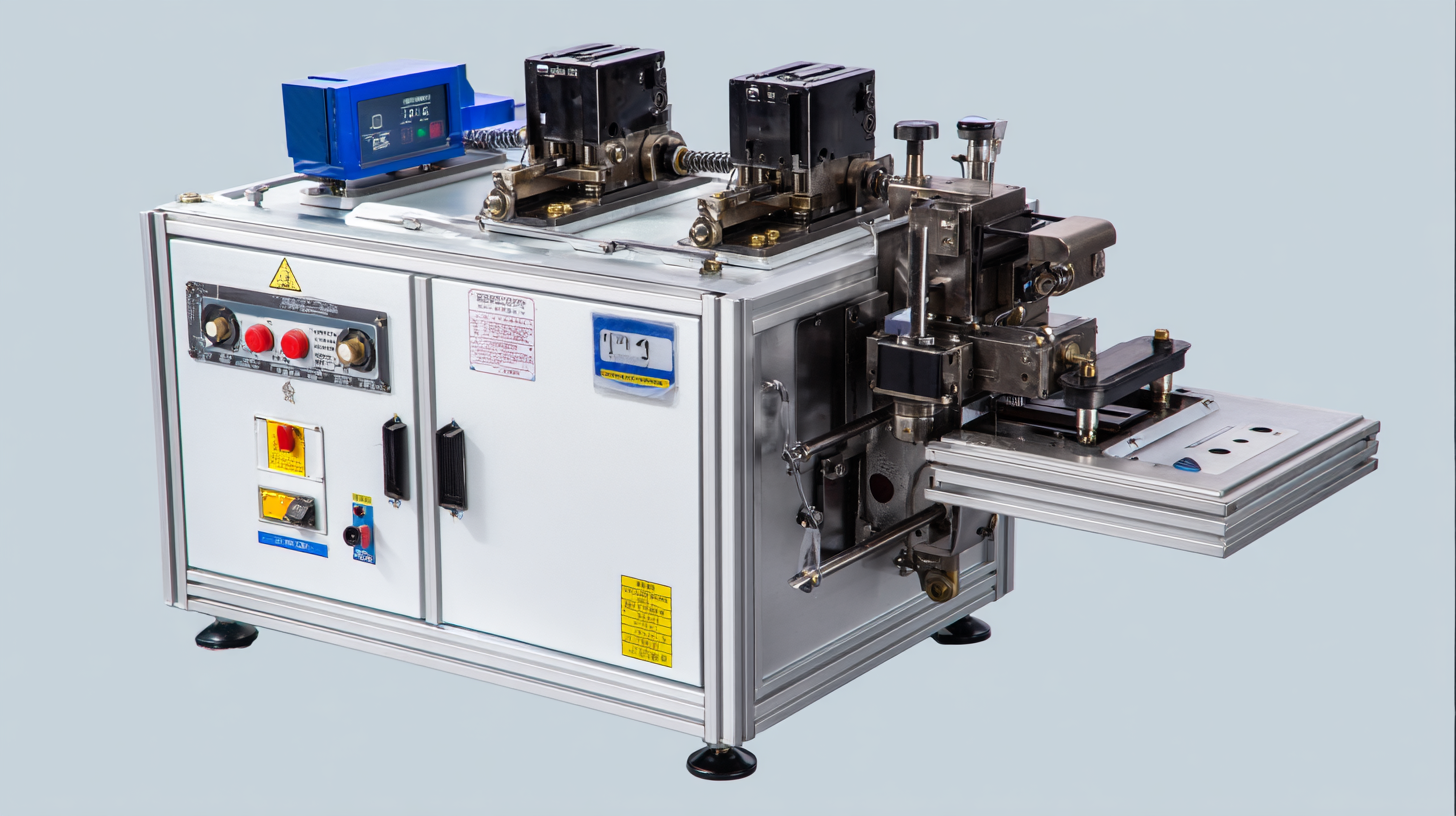

In the rapidly evolving world of manufacturing, selecting the right equipment is crucial for enhancing productivity and maintaining quality. One such pivotal machine is the Resistance Sealing Nail Welding Machine, which plays a fundamental role in various industrial applications, particularly in construction and furniture production. With an overwhelming array of options available in the market, choosing the best machine can be daunting. However, understanding the key factors that define quality and efficiency in these machines can simplify the decision-making process. In this blog, we will explore five essential secrets that will guide you in identifying the most suitable Resistance Sealing Nail Welding Machine for your specific needs, ensuring that you make an informed investment that maximizes performance and durability.

When selecting a resistance sealing nail welding machine, it’s essential to delve into the key industry standards and specifications that dictate performance and compliance. Understanding these standards helps manufacturers and contractors optimize their processes while ensuring quality and safety. This knowledge is particularly crucial as industries shift toward sustainable practices. Emerging trends show a growing emphasis on integrating innovative technologies that not only enhance the performance of welding machines but also align with broader environmental goals.

In addition to traditional specifications, recent developments in performance standards emphasize desired outcomes rather than strict adherence to recipes or methods. This flexibility can lead to improved efficiency and reduced costs, as companies are encouraged to innovate within frameworks designed for sustainability. As the construction industry increasingly adopts advanced materials and techniques, ensuring that welding machines meet these evolving standards will be vital in maintaining competitive advantage while contributing to a greener future. Embracing these changes will ensure that companies can meet both current demands and future challenges, particularly as regulations around sustainability tighten.

When it comes to selecting a resistance sealing nail welding machine, performance metrics are crucial for determining machine efficiency. The key metrics to assess include cycle time, energy consumption, and weld strength. A machine that boasts a shorter cycle time can significantly increase productivity, allowing for faster operations without compromising quality. Meanwhile, lower energy consumption not only reduces operational costs but also indicates a more efficient system, which is essential for businesses looking to optimize their processes.

Additionally, weld strength is a non-negotiable factor in evaluating the machine's performance. Strong, consistent welds ensure product reliability, which is vital in industries where safety and durability are paramount. Potential buyers should consider machines that provide comprehensive data on these performance metrics, allowing for informed decisions based on quantifiable assessments. By focusing on these criteria, businesses can invest in equipment that not only meets their current needs but is also adaptable for future demands, ensuring long-term success in nail welding applications.

| Machine Model | Welding Speed (nails/min) | Energy Consumption (kW) | Operating Voltage (V) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 150 | 5.0 | 240 | 85 | 200 |

| Model B | 120 | 6.5 | 220 | 80 | 250 |

| Model C | 180 | 4.0 | 230 | 90 | 195 |

| Model D | 140 | 5.5 | 240 | 78 | 210 |

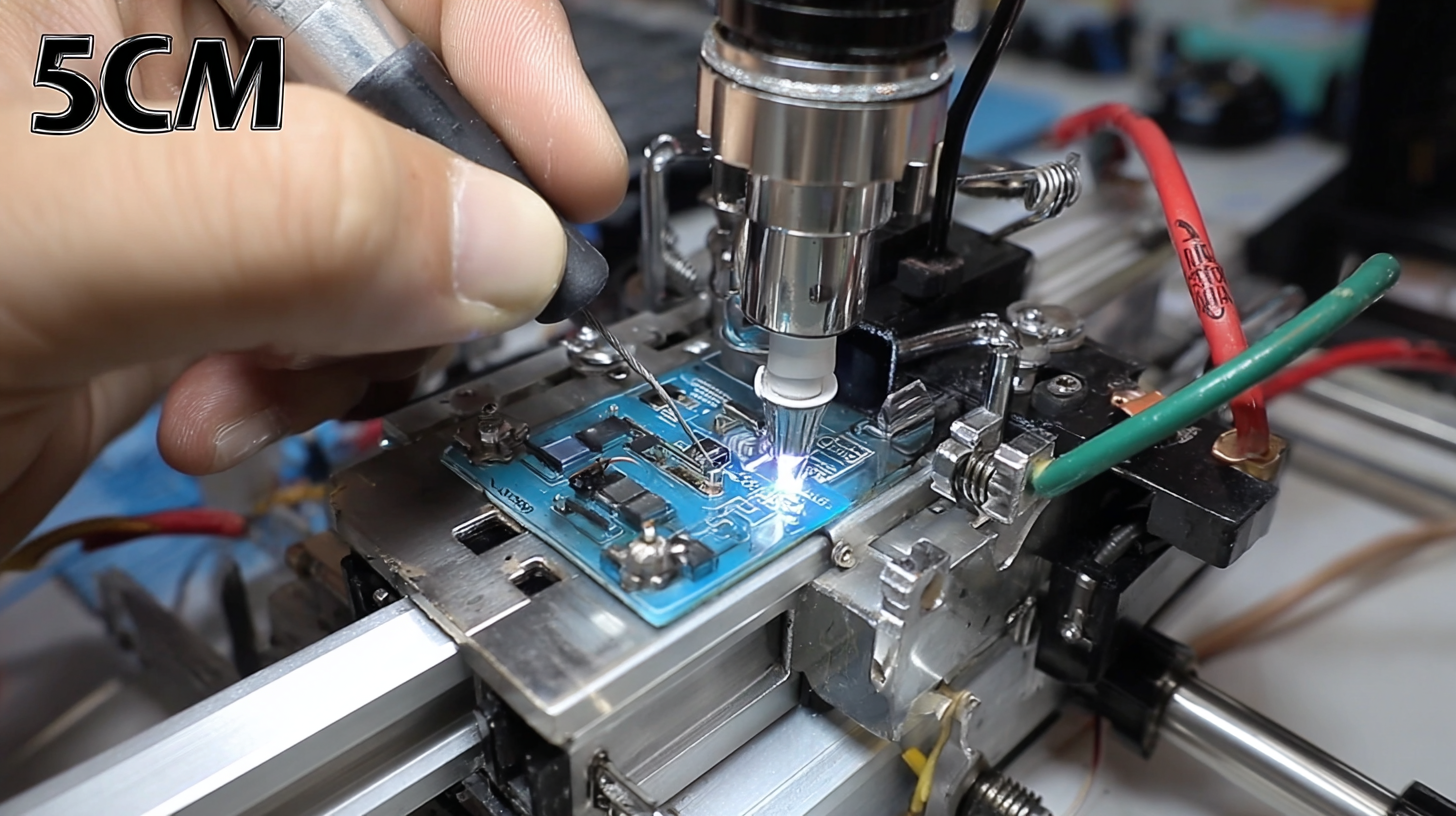

When it comes to selecting a resistance sealing nail welding machine, the importance of material choice cannot be overstated. The components utilized in the welding process, such as electrical contacts, electrodes, and the materials being welded, directly affect the quality and durability of the final product. For instance, using high-conductivity copper for electrodes can significantly enhance the efficiency of heat transfer during the welding process, leading to stronger welds. Additionally, ensuring that the compatibility of materials being welded is optimal will minimize the risk of defects and improve overall performance.

Moreover, the selection of the right insulation materials is critical for maintaining the integrity of the welding process. Insulation that can withstand high temperatures and resist wear will not only extend the lifespan of the welding machine but also uphold safety standards. It's essential to evaluate the thermal and electrical properties of the materials involved to achieve the best welding results. By prioritizing the right components, welders can ensure consistent quality in their projects, ultimately leading to greater satisfaction and success in their applications.

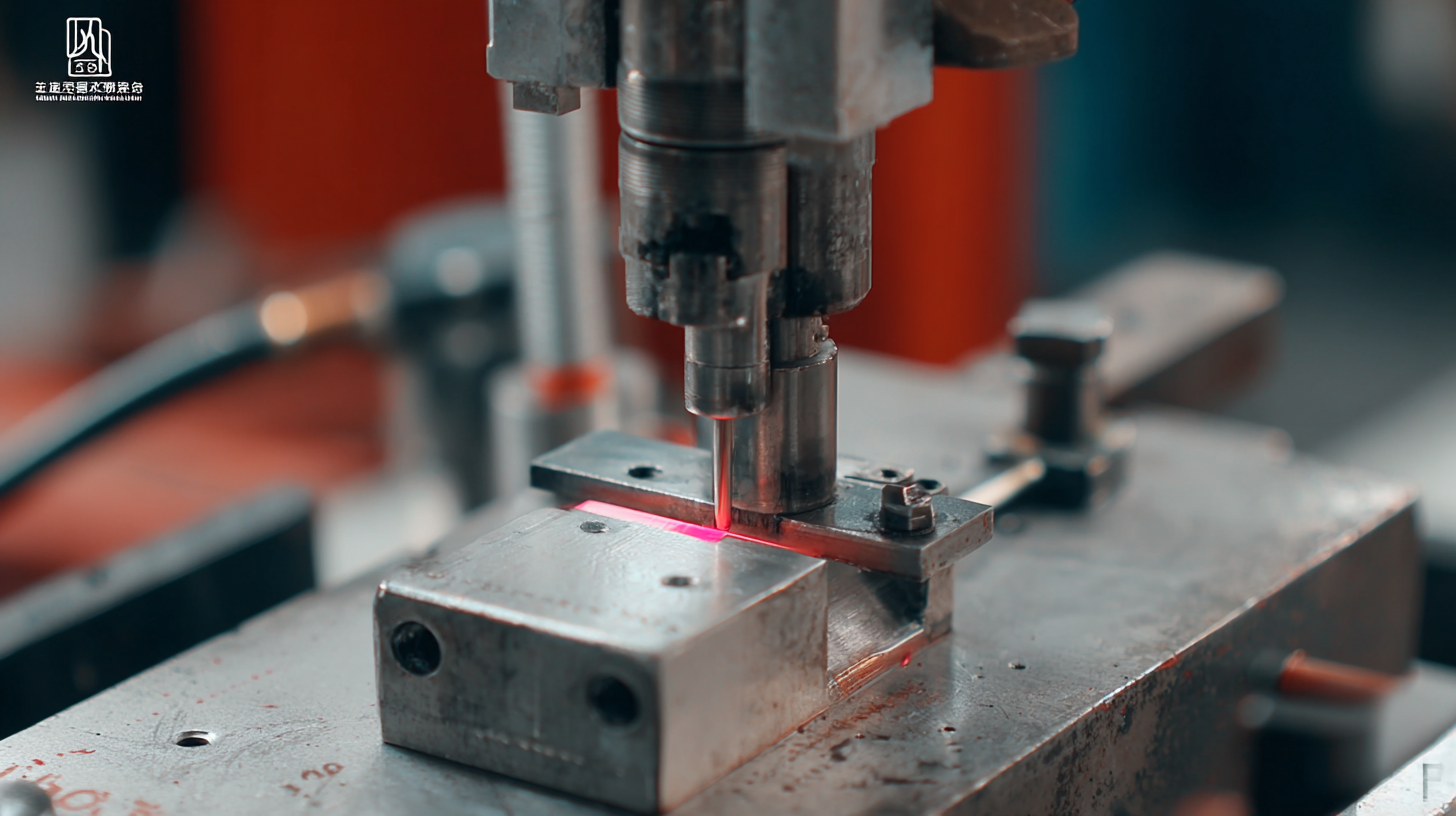

When considering resistance sealing nail welding equipment, safety standards must be your top priority. In a recent report by the International Institute of Welding, approximately 30% of welding-related accidents occur due to non-compliance with safety regulations. Proper adherence to guidelines such as ISO 3767 and ANSI Z49.1 can significantly mitigate risks. These standards outline essential safety measures, including proper protective gear and machine maintenance protocols.

Tip: Always check if the equipment complies with relevant safety standards before purchasing. This ensures that you are investing in a machine that prioritizes the safety of its users and minimizes accident risks.

Moreover, employing equipment that features automatic safety shut-offs and thermal overload protection is crucial. According to research published in the Journal of Occupational Safety and Health, machines with these features reduce the likelihood of injury by up to 45%. Ensuring that the welding machine integrates these safety mechanisms not only safeguards the personnel involved but also enhances overall productivity.

Tip: Regularly train your staff about the latest safety protocols and the specific equipment they are using. Continuous education fosters a safety-first culture, reducing accidents and improving workplace morale.

When selecting an industrial resistance sealing nail welding machine, it's crucial to weigh cost against quality to ensure long-term value. According to a report by the International Institute of Welding, high-quality welding machines can vastly improve production efficiency, with users reporting a 20-30% reduction in operational costs over time. While initially more expensive, investing in a reliable machine can lead to significant savings in maintenance and downtime.

Tip 1: Always consider the machine's performance metrics, such as duty cycle and power output. A machine that performs efficiently under demanding conditions can save you from costly repairs or replacements in the future.

Quality also influences the longevity and reliability of the equipment. A market analysis from Equipment Today highlights that industrial machines with high durability ratings tend to show a marked decrease in failure rates, leading to extended service life. This ensures that your production line remains uninterrupted, directly impacting overall profitability.

Tip 2: When evaluating options, look for warranties and customer support. A strong warranty often indicates the manufacturer’s confidence in their product quality, providing peace of mind and potential savings in case of unexpected issues.

By analyzing these factors, businesses can make informed decisions that align their budget with quality requirements, ultimately enhancing operational efficiency and ROI in the long run.