Leave Your Message

The demand for efficient and high-quality packaging solutions has led to a significant interest in products like the China Vacuum Static Box. According to a recent industry report by Smithers Pira, the global market for vacuum packaging is expected to reach $30.9 billion by 2024, underscoring the importance of choosing the right equipment for optimal performance. The China Vacuum Static Box, known for its robust design and advanced technology, plays a crucial role in preserving product integrity and extending shelf life across various sectors, including food and pharmaceuticals.

As organizations increasingly prioritize sustainability and efficiency in their packaging operations, understanding the key features, manufacturing standards, and operational benefits of these boxes becomes essential for maximizing their investment and operational efficiency. This blog aims to guide you through the critical considerations necessary for selecting the best China Vacuum Static Box tailored to your specific needs.

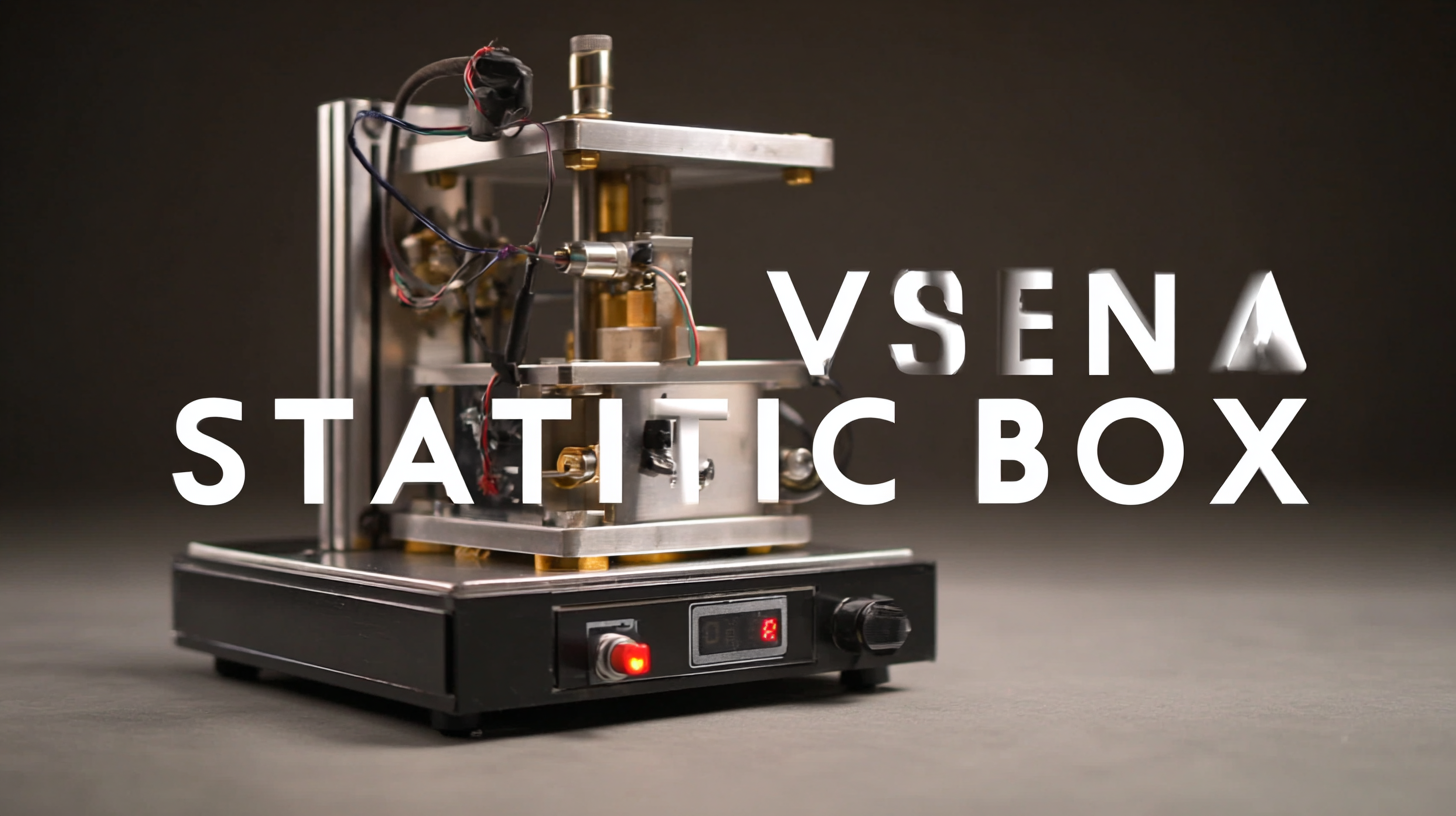

Vacuum static boxes play a crucial role in various industrial applications, primarily in managing and optimizing the environment for sensitive processes. These specialized containers create an airtight environment that minimizes exposure to contaminants, which can significantly affect the quality and integrity of products. According to a recent report by MarketsandMarkets, the global vacuum packaging market is expected to reach $52 billion by 2027, reflecting a growing demand for efficient packaging solutions that preserve product quality.

When choosing the best China vacuum static box, evaluating its efficiency is crucial to maximizing operational performance. Key metrics to consider include thermal performance, vacuum integrity, and material durability. According to a report from the National Institute of Standards and Technology (NIST), optimal thermal performance can enhance the energy efficiency of vacuum applications by up to 30%. This translates to significant energy savings and improved productivity in industrial settings where consistent temperature control is vital.

Vacuum integrity is another critical factor, as the effectiveness of a vacuum static box is heavily reliant on its ability to maintain low-pressure conditions. Research by the International Vacuum Society highlights that a box with a vacuum retention of less than 5 mTorr minimizes contamination risks, thereby enhancing the quality of the end product. Additionally, material durability plays a significant role; a study from the Materials Research Society found that static boxes crafted from advanced composites exhibit a lifespan increase of 20% compared to traditional materials. Taking these metrics into account ensures a well-rounded evaluation when selecting the right China vacuum static box for specific operational needs.

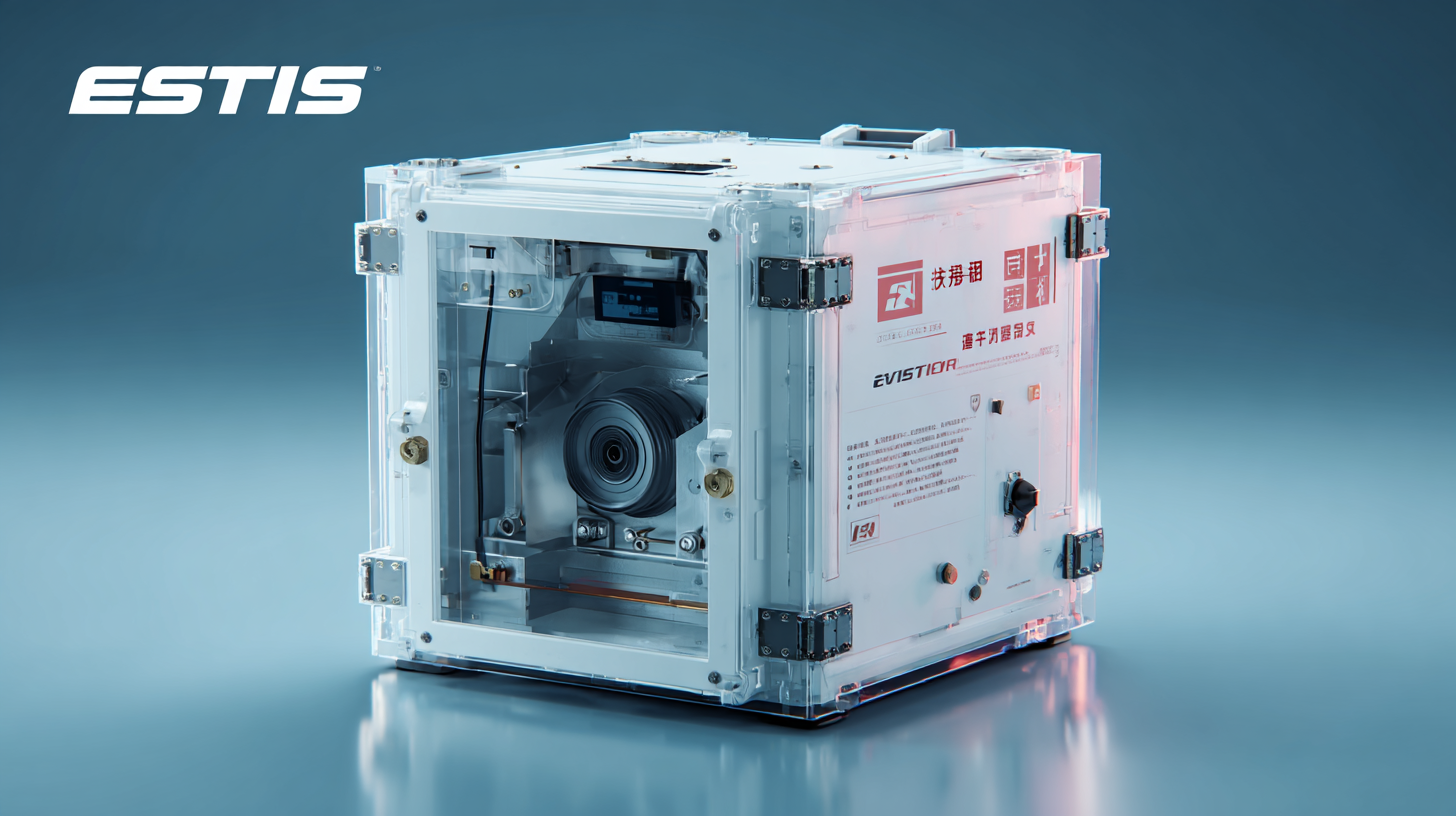

When selecting a vacuum static box, the choice of materials plays a pivotal role in achieving optimal performance. Research indicates that materials such as stainless steel and plastics have distinct thermal and durability properties that can significantly impact efficiency. For instance, stainless steel offers superior resistance to high temperatures and is known for its longevity, making it ideal for applications requiring extended use under extreme conditions. Conversely, advanced polymers can provide lightweight yet robust options, which could reduce maintenance costs and enhance maneuverability in various settings.

**Tip:** Always consider the specific application requirements when choosing a material. If your process involves corrosive substances, stainless steel may be the better option, while non-reactive applications might benefit from high-grade plastics.

Additionally, a recent industry report highlighted that vacuum boxes made with composite materials are gaining traction, offering a hybrid approach that balances strength and weight. This innovation allows for higher insulation values, which can contribute to energy savings and improved overall performance. Evaluating the thermal conductivity and overall structural integrity of materials can make a significant difference in the effectiveness of vacuum static boxes.

**Tip:** Don’t overlook the importance of the manufacturing process. Evaluate suppliers based on their quality assurance practices to ensure the longevity and reliability of the materials used in the vacuum static box.

| Material Type | Thermal Conductivity (W/m·K) | Weight (kg) | Durability | Cost ($/unit) | Efficiency Rating (1-10) |

|---|---|---|---|---|---|

| Aluminum | 205 | 2.7 | High | 50 | 9 |

| Stainless Steel | 16 | 8.0 | Very High | 75 | 8 |

| Polycarbonate | 0.2 | 1.2 | Moderate | 30 | 7 |

| Fiberglass | 0.04 | 1.5 | High | 40 | 6 |

| Carbon Fiber | 45 | 2.0 | Very High | 120 | 10 |

When selecting a vacuum static box, efficiency is paramount to ensure optimal performance in industrial applications. To enhance the vacuum static box's efficiency, first, consider the materials used in construction. High-quality materials can better withstand pressure differences and minimize leakage, which is essential for maintaining an effective vacuum environment.

Another critical aspect is the design of the vacuum static box itself. Ensuring that the box is ergonomically shaped and properly sized for your specific needs can drastically improve efficiency. A well-designed box allows for uniform suction across all areas, preventing dead spots where energy and resources are wasted.

Tips:

When selecting a vacuum static box in China, it's crucial to be aware of common pitfalls that can hinder efficiency and performance. One significant mistake is failing to conduct thorough research on suppliers. Many buyers rush into purchasing decisions without vetting manufacturers, which can lead to subpar quality products. It's important to check the supplier's credentials, read customer reviews, and ask for product samples whenever possible. This due diligence helps ensure that the vacuum static box meets both quality standards and your operational needs.

Another common issue is overlooking the specifications and features of the vacuum static box. Buyers often focus solely on price, neglecting to consider the material, design, and functionality that can significantly impact efficiency. Ensure that the box is suited for your specific application requirements, including temperature tolerances and pressure levels. Additionally, assess whether the box includes essential features like proper sealing mechanisms and durability, as these factors play a vital role in achieving maximum efficiency and longevity of the equipment. By avoiding these pitfalls, you can make a more informed and effective choice in your vacuum static box selection.