Leave Your Message

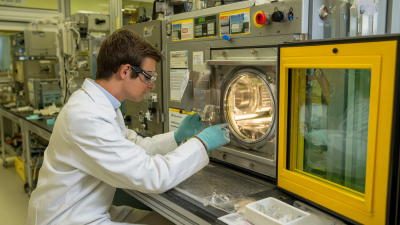

The Single-Station Series Vacuum Glove Box has emerged as an essential tool in various scientific and industrial applications, providing a controlled environment that minimizes contamination and exposure to air. This innovative system allows researchers and professionals to handle sensitive materials safely, making it particularly valuable in fields such as chemistry, pharmaceuticals, and materials science. The design of the Single-Station Series Vacuum Glove Box ensures that all operations can be performed with precision and under optimal conditions, enhancing the quality of results and safety for the user.

Furthermore, the benefits of utilizing a Single-Station Series Vacuum Glove Box extend beyond mere safety; it also facilitates efficient workflows by streamlining processes and reducing the risk of chemical reactions with ambient moisture and oxygen. By maintaining a stable vacuum environment, this equipment can support a wide array of experiments and manufacturing processes, ultimately leading to improved productivity and accuracy. As we delve into the applications and advantages of the Single-Station Series Vacuum Glove Box, it is clear that its role is pivotal in advancing both research methodologies and industrial practices.

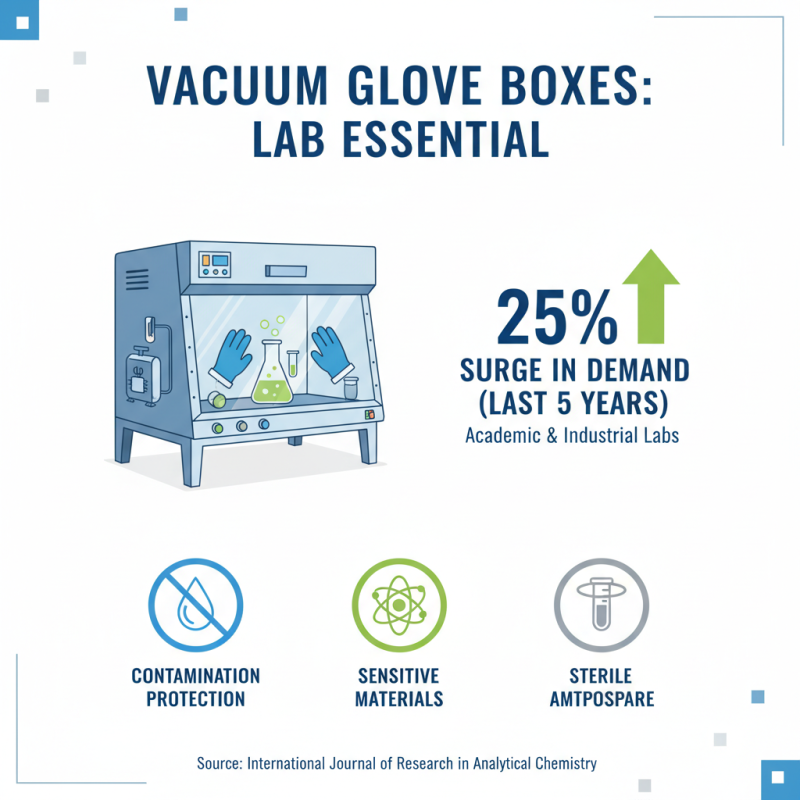

Single station series vacuum glove boxes are essential tools in laboratories that require a controlled environment for sensitive materials. These devices are designed to provide maximum protection against contamination, ensuring that experiments are conducted in a sterile atmosphere. According to a report from the International Journal of Research in Analytical Chemistry, the demand for glove boxes in academic and industrial laboratories has surged by approximately 25% over the last five years, underscoring their significance in modern scientific research.

In laboratory applications, these vacuum glove boxes are widely employed for handling air-sensitive compounds, toxic substances, and highly reactive chemicals that can compromise both safety and experimental integrity. They create a low-humidity and inert atmosphere, preventing unwanted reactions with moisture and oxygen. A study by the Laboratory Equipment Manufacturer Association reveals that the use of vacuum glove boxes has resulted in a 30% increase in the reliability of experimental outcomes, demonstrating their crucial role in achieving accurate and reproducible results in chemical synthesis and material science research.

Furthermore, single station series vacuum glove boxes facilitate a range of applications, such as the preparation of nanomaterials and the synthesis of pharmaceuticals, where exposure to moisture can lead to product degradation. They are also invaluable in the field of electronics, where sensitive components must be assembled in a contamination-free environment. As the research landscape continues to evolve, the adoption of advanced vacuum technology is set to bolster innovation and efficiency in laboratory practices, showcasing the vital benefits these systems offer to scientific exploration.

Vacuum glove boxes are essential tools in many controlled environments, providing a sterile and secure space for handling sensitive materials. One of the key benefits of utilizing these devices is their ability to maintain a controlled atmosphere. By creating a low-pressure environment, vacuum glove boxes can effectively exclude contaminants such as moisture, oxygen, and other airborne particles that could compromise the integrity of the materials being worked on. This is particularly vital in fields like pharmaceuticals, nanotechnology, and material science, where even the slightest impurity can lead to adverse outcomes.

Tips for maximizing the efficacy of your vacuum glove box include regular maintenance checks to ensure seals and gloves are in optimal condition. It's also beneficial to familiarize yourself with the specific properties of the materials you're working with, allowing for better control over the environmental settings inside the box. Implementing a systematic approach to sample handling can help streamline processes and minimize the risk of contamination, which is crucial for producing reliable and reproducible results.

Another significant advantage of vacuum glove boxes is the enhanced safety they offer. By isolating hazardous materials or sensitive reactions from external environments, these systems significantly reduce the risk of accidents and exposure. Utilizing proper training and protocols among users can further enhance safety measures, ensuring that all operators are well-acquainted with the risks and operational procedures of the glove box. This focus on safety not only protects personnel but also contributes to the overall success of projects requiring stringent environmental controls.

The integration of single station series vacuum glove boxes into various industrial applications has shown significant efficiency improvements across multiple sectors. These glove boxes create a controlled environment, maintaining inert atmospheres that are critical for processes involving sensitive materials, such as chemicals, pharmaceuticals, and electronic components. By minimizing exposure to contaminants, companies can enhance the quality of their products while also reducing the chances of batch failures. This controlled setting allows for more precise handling and manipulation of materials, ultimately leading to faster production times and improved yield rates.

In specific industries, the utilization of glove boxes has led to quantifiable advancements in operational efficiency. For example, in the pharmaceutical sector, the use of these systems has streamlined drug formulation processes, resulting in shorter development cycles. In the electronics industry, glove boxes facilitate the safe assembly of sensitive components, which reduces the risk of damage and waste during production. Industry data highlights that organizations employing glove boxes have reported reductions in material loss by up to 40%, along with noticeable increases in throughput and overall productivity. These benefits illustrate the vital role that glove box technology plays in enhancing operational efficiency while ensuring safety and quality control in various applications.

The use of single station glove boxes has gained significant traction in various research and industrial settings, primarily due to their enhanced efficiency and safety compared to traditional methods. According to a report by Smith Research Group, the adoption of single station series vacuum glove boxes has increased by 40% in laboratory environments over the past five years. These advanced systems provide a controlled atmosphere that is essential for working with sensitive materials, thereby mitigating contamination risks that are prevalent in open systems.

In contrast, traditional methods often rely on ambient conditions, leading to a higher probability of cross-contamination and exposure to environmental variables. A comparative study conducted by the National Industrial Research Institute indicated that glove boxes reduce contamination incidents by up to 70% when handling hazardous substances. This marked difference in contamination control not only protects the integrity of samples but also ensures the safety of laboratory personnel. The ergonomic design of single station glove boxes further enhances operational comfort, allowing for prolonged use without fatigue, which is often a concern with conventional handling techniques. Such advantages make single station glove boxes a preferred choice for modern laboratories seeking efficiency and safety in their operations.

| Feature | Single Station Glove Box | Traditional Methods |

|---|---|---|

| Isolation Efficiency | High, with minimal contamination risk | Moderate, increased contamination risk |

| Ease of Use | User-friendly design for operators | Typically requires more training |

| Cost-Effectiveness | Higher initial investment, lower long-term costs | Lower initial cost, higher operational costs |

| Space Requirement | Compact design suitable for limited spaces | May require more floor space |

| Material Compatibility | Compatible with a wide range of materials | Limited compatibility depending on setup |

The future of vacuum glove box technology is poised for remarkable advancements, driven by the increasing demand for precision and safety in various fields, such as pharmaceuticals, electronics, and research laboratories. Innovations focusing on automation and enhanced material science will redefine how these systems function, providing users with greater control and efficiency. For instance, the integration of IoT (Internet of Things) capabilities is set to allow for real-time monitoring and remote access, making it easier for scientists and engineers to manage processes and ensure optimal conditions within the glove box.

Tips for users considering upgrading their glove box systems include evaluating the latest technological features, such as automated seal testing and user-friendly interfaces. Additionally, investing in energy-efficient models can lead to long-term savings and reduced environmental impact. As safety becomes paramount, look for glove boxes that utilize advanced filtration systems and offer customizable features tailored to specific application needs.

Another promising trend is the use of smart materials that can adapt to changes in external conditions, thus enhancing the overall functionality of vacuum glove boxes. These materials could provide better durability and resistance against chemical wear, ultimately improving the lifespan of the equipment. As research continues to evolve, staying informed about these trends will be essential for users aiming to maintain high standards in their work.