Leave Your Message

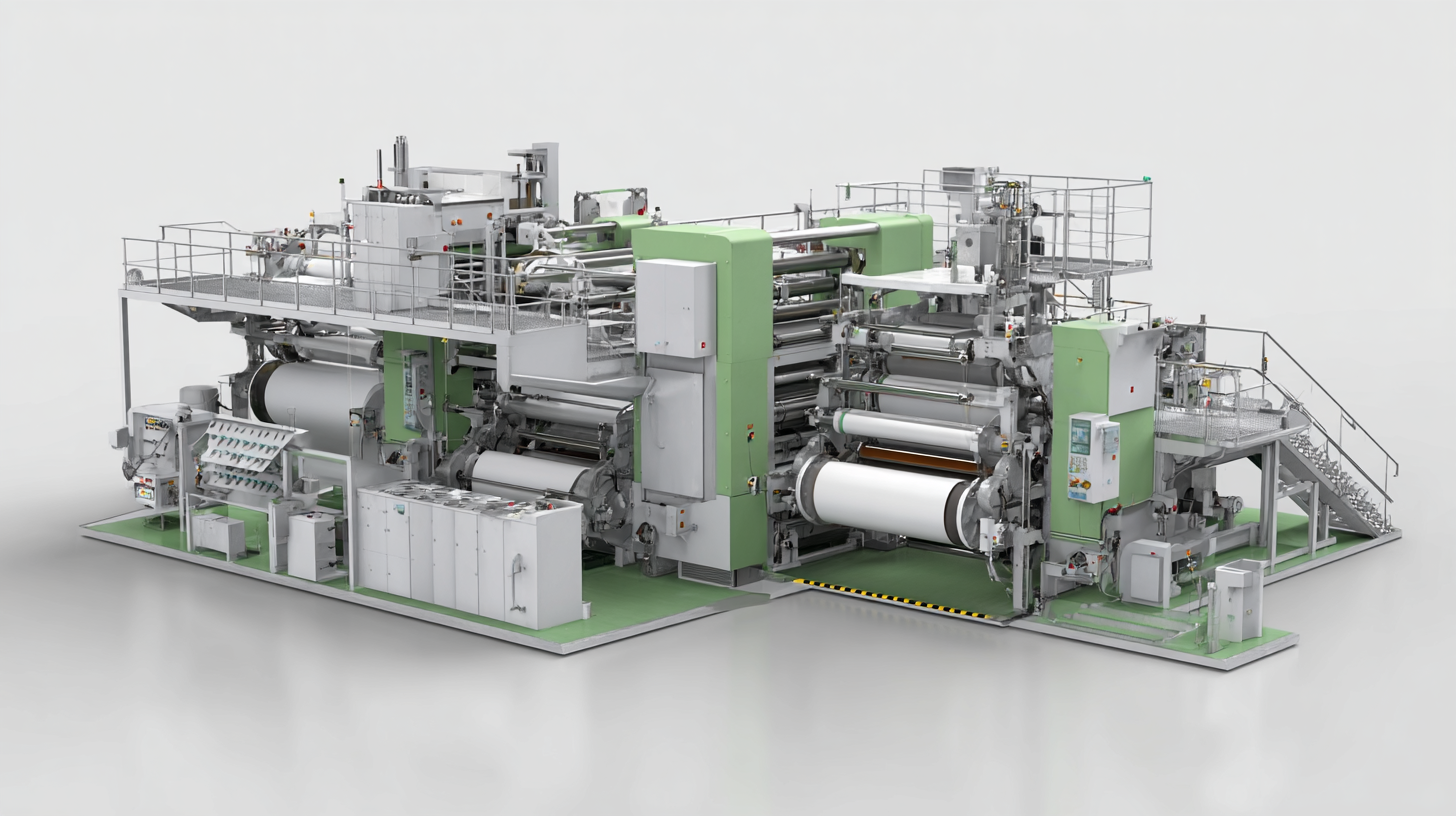

In the rapidly evolving manufacturing sector, understanding the nuances of equipment selection is paramount for optimizing production efficiency. One crucial piece of machinery that has gained significant attention is the Integrated Calendering and Slitting Machine, essential for industries such as textiles and plastics. According to a recent market research report by Grand View Research, the global market for slitting and calendering machinery is projected to reach USD 2.7 billion by 2025, driven by the increasing demand for high-quality finished products in the manufacturing supply chain. This growth underscores the importance of selecting the right Integrated Calendering and Slitting Machine to enhance operational productivity and meet stringent industry standards. As manufacturers navigate the complexities of import and export certifications, aligning equipment choice with production needs and compliance regulations becomes imperative for sustaining competitive advantage.

The integration of calendering and slitting machines in modern manufacturing processes offers significant advantages that directly impact productivity and cost-efficiency. A recent study highlights a remarkable shift in the production landscape, particularly in the manufacturing of cylindrical lithium-ion batteries. The adoption of tabless electrodes has been shown to reduce manufacturing costs from 2.029 to 1.698 €/kWh, illustrating the potential for integrated machinery to streamline operations and lead to substantial cost savings.

By incorporating advanced calendering and slitting technologies, manufacturers can achieve superior material handling and cutting precision. This integration not only enhances the quality of the final product but also optimizes the overall production cycle, resulting in decreased waste and increased throughput. Additionally, the efficient setup of these machines allows for quicker transitions between different production tasks, further rationalizing the manufacturing workflow.

Moreover, as industries increasingly move towards sustainable practices, integrated calendering and slitting machines facilitate the use of innovative materials that may contribute to overall sustainability goals. In summary, the benefits of these machines extend beyond mere financial savings, playing a crucial role in enhancing operational efficiency and supporting the transition to more sustainable manufacturing methods.

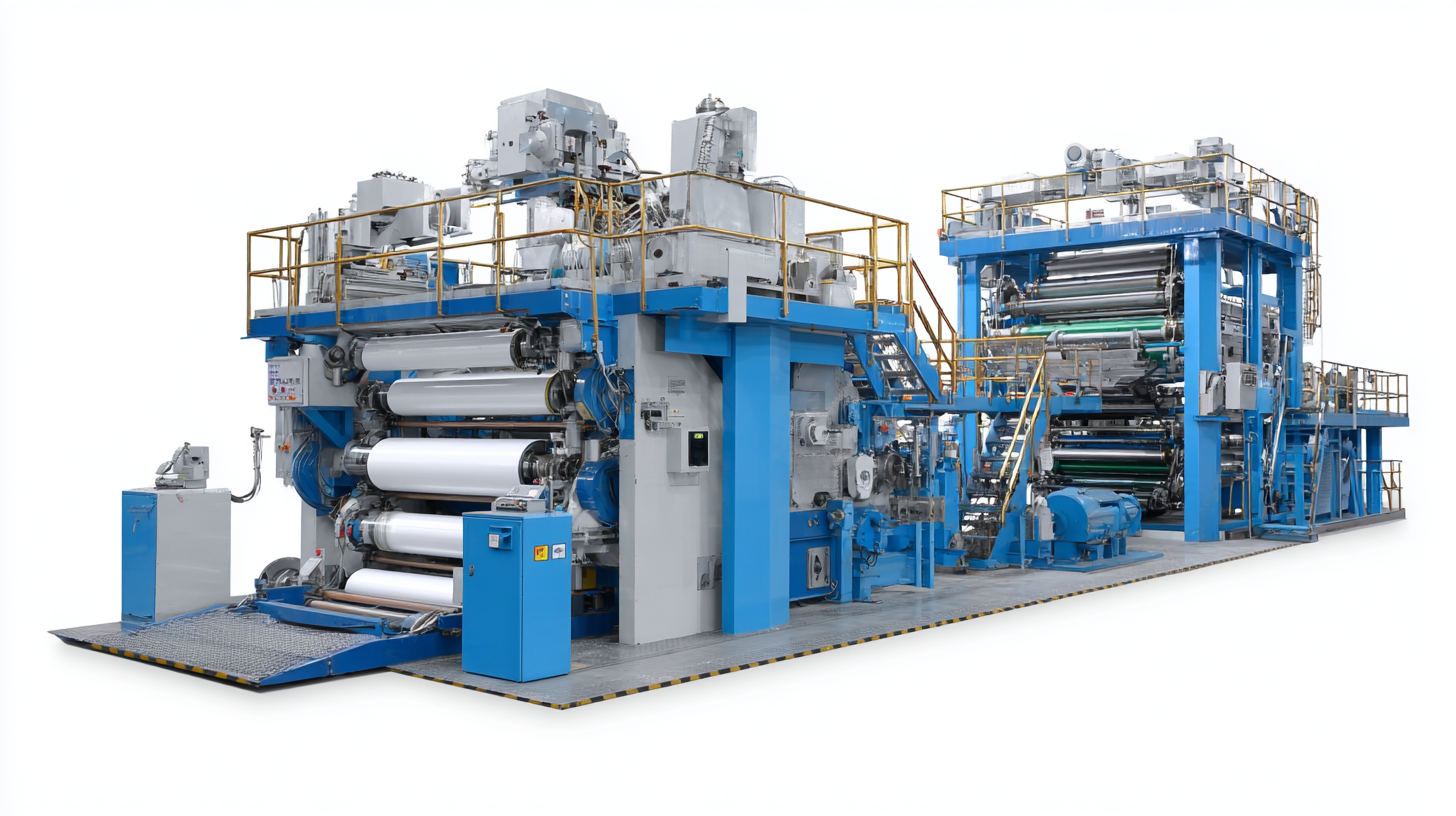

When selecting the right integrated calendering and slitting machine for your production needs, it's crucial to focus on key features that enhance efficiency and output quality. The ability to adjust tension and speed is paramount; a 2022 industry report from TechNavio indicated that machines with variable speed drives can reduce waste by 15-20%, leading to significant cost savings. Additionally, look for features such as automated control systems that streamline operations and minimize human error, supporting a more consistent product quality.

Tips for your selection process include evaluating the machine's versatility in handling different materials and thicknesses. A machine that accommodates a wider range of substrates can offer more flexibility in production, allowing you to respond quickly to market demands. Furthermore, consider the after-sales support and training provided by the manufacturer. A reliable service team can significantly reduce downtime, especially during the initial setup phase.

Lastly, energy efficiency should not be overlooked. According to a study by the International Energy Agency, modern machines that utilize energy-efficient technology can decrease operational costs by up to 30%. Opt for machines that come with energy-saving features, as this will not only benefit your bottom line but also contribute to a more sustainable manufacturing process.

When selecting an integrated calendaring and slitting machine for production needs, understanding the competitive landscape of top brands is crucial. Each manufacturer offers unique features designed to address specific production challenges. For instance, a recent study indicated that efficiency in material usage can account for up to 20% of total production costs, making advanced slitting technology a significant factor in ROI. Brands that incorporate smarter automation tools often report a reduction in material waste and enhanced throughput.

Furthermore, a comparative analysis of advanced calendaring machines reveals critical differentiators among market leaders. Innovations such as real-time monitoring and predictive maintenance capabilities are becoming standard, elevating production reliability. According to industry forecasts, companies that leverage integrated machinery with high levels of automation can expect to see a 15-25% boost in overall equipment effectiveness (OEE), positioning them ahead in the competitive manufacturing market. As you evaluate options, focusing on these differentiators will empower your decision-making process and align your production setup with long-term profitability goals.

When selecting an integrated calendaring and slitting machine, customer testimonials can provide invaluable insights into real-world performance. According to a recent report by the Textile Machinery Association, over 75% of manufacturers highlight efficiency and precision as critical factors when evaluating machinery. One customer, a leading textile producer, shared how their new calendaring machine reduced production time by 30%, leading to a significant increase in output. This aligns with data indicating that advanced calendaring technologies can enhance fabric quality while minimizing waste, thereby boosting overall productivity in the manufacturing process.

Moreover, the importance of after-sales support and reliability cannot be overlooked. A study from the Industry Research Bureau noted that 68% of companies consider customer support as a decisive factor in choosing their machinery supplier. A testimonial from a plastic film manufacturer emphasized that their supplier's prompt technical assistance was crucial in minimizing downtime, which ultimately protected their profit margins. These real-world experiences underscore the necessity of not just assessing the technical specifications of a machine but also considering the performance reliability and support from the manufacturer, which are integral to maintaining a successful operation.

When it comes to maintaining an integrated calendaring and slitting machine, regular upkeep can significantly enhance its longevity and efficiency. One of the key maintenance tips is to schedule routine inspections to identify wear and tear early. Keeping an eye on the rollers and blades for signs of damage can prevent costly downtimes and ensure optimal performance during production.

Another important aspect of maintenance is the lubrication of moving parts. Proper lubrication minimizes friction, which can lead to overheating and unnecessary wear on components. Make sure to follow the manufacturer’s recommendations for lubrication intervals and types of lubricant to use. Additionally, consider implementing a cleaning routine to remove dust and debris, as these can affect the machine’s functionality.

Lastly, training your operators on best practices for machine usage also contributes to extending its lifespan. Encourage them to follow operational guidelines closely and report any irregular sounds or performance issues immediately. By fostering a culture of care and diligence around machine operation, you can help safeguard your investment while ensuring consistent productivity.