Leave Your Message

In the rapidly evolving landscape of battery manufacturing, the optimization of production processes is paramount for maintaining competitiveness and achieving sustainability goals. The 32140 Cylindrical Battery Pilot Line presents a cutting-edge solution that not only enhances efficiency but also caters to the increasing demand for high-capacity energy storage systems. According to a report by the International Energy Agency, global battery demand is projected to grow by over 30% annually through 2030, underscoring the need for innovative production strategies. Implementing advanced technologies in the 32140 Cylindrical Battery Pilot Line enables manufacturers to streamline operations and reduce waste, thus maximizing output while minimizing environmental impact. This pilot line serves as a critical cornerstone for manufacturers aiming to harness advancements in battery technology and meet the surging market requirements effectively.

To enhance production efficiency in 32140 cylindrical battery pilot lines, it's crucial to concentrate on streamlined processes and innovative technologies.

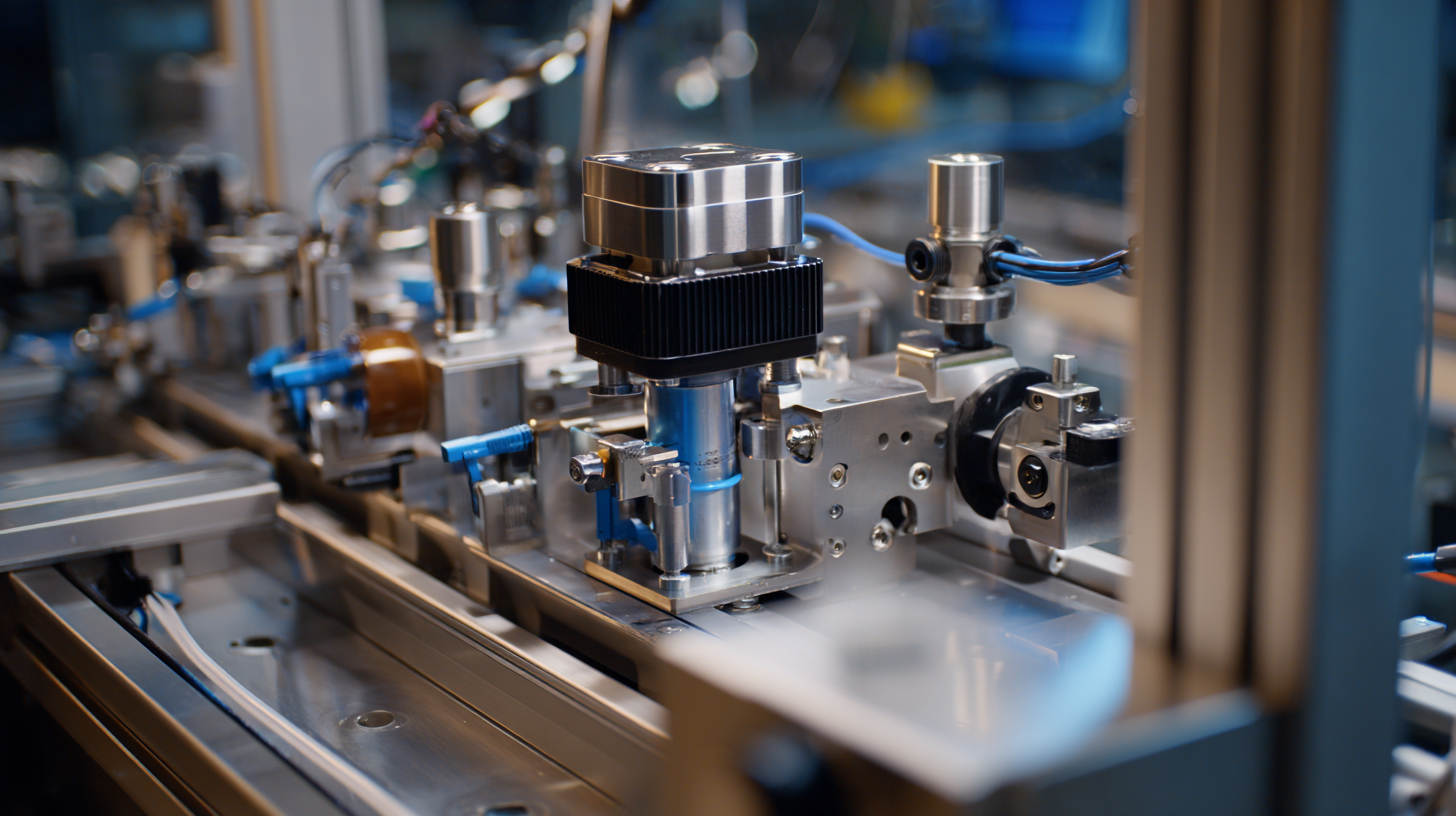

Adopting automation can significantly reduce manual errors and speed up production cycles. Implementing real-time monitoring systems allows for instant feedback on production performance, enabling quick adjustments to maintain optimal output.

Tips: Invest in smart sensors that track battery performance during the manufacturing process. This data-driven approach ensures that any deviations from quality standards are addressed immediately, preventing costly rework.

Another effective strategy is to optimize the layout of the pilot line itself. A well-designed workflow can minimize unnecessary movement and handling, which not only saves time but also reduces the risk of damage to sensitive components.

Tips: Conduct a time-and-motion study to identify bottlenecks in the current process. Use this information to restructure the production line in a way that promotes a smooth and continuous flow of materials.

In today's rapidly evolving battery production sector, optimizing efficiency is crucial. Key Performance Indicators (KPIs) serve as essential tools for assessing the capability and productivity of battery manufacturing processes. Notably, metrics such as cycle time, yield rate, and equipment effectiveness provide insights into operational performance. According to a recent report by the International Energy Agency (IEA), manufacturers can enhance battery production efficiency by as much as 20% through the diligent tracking of these KPIs.

Another critical KPI is the first-pass yield (FPY), which measures the percentage of products produced correctly without rework. The Benchmarking Battery Production report highlights that leading manufacturers achieve FPYs exceeding 95%, indicating high-quality outputs. Additionally, analyzing production downtime can reveal valuable information for process optimization. A study by McKinsey suggests that reducing downtime by just 10% can lead to a significant increase in overall capacity utilization. By focusing on these KPIs, manufacturers can effectively maximize the efficiency of their 32140 cylindrical battery pilot lines, driving better results in a competitive marketplace.

| Key Performance Indicators | Current Value | Target Value | Status |

|---|---|---|---|

| Production Yield (%) | 85 | 95 | Under Target |

| Cycle Time (minutes) | 12 | 10 | Over Target |

| Defect Rate (%) | 5 | 2 | Over Target |

| OEE (Overall Equipment Effectiveness) (%) | 75 | 85 | Under Target |

| Energy Consumption (kWh per unit) | 1.5 | 1.2 | Over Target |

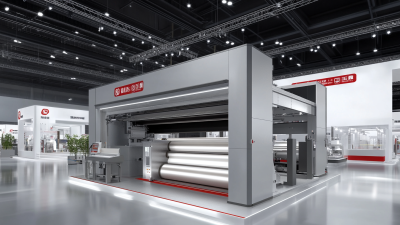

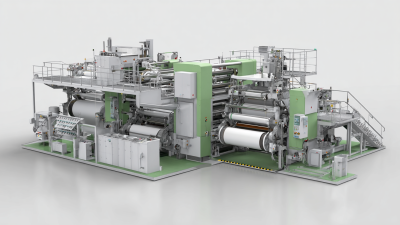

The advancement of technology in the manufacturing of 32140 cylindrical batteries is unlocking unprecedented efficiencies. Innovations such as automated assembly lines and precision robotics are significantly reducing production times while enhancing quality control. These technologies streamline the entire manufacturing process, from electrode preparation to cell assembly, ensuring that each component meets stringent specifications. Moreover, advanced machine learning algorithms are being utilized to predict maintenance needs, minimizing downtime and further maximizing production capabilities.

Another crucial factor in boosting the efficiency of 32140 cylindrical battery production is the integration of digital twins. By creating virtual replicas of the manufacturing process, companies can simulate and analyze various scenarios to identify potential bottlenecks and optimize workflow. This not only enables real-time monitoring but also aids in better resource management, leading to cost savings. The combination of these technological innovations positions manufacturers to increase their output and improve the overall quality of their products, paving the way for a more efficient future in battery manufacturing.

In the rapidly evolving landscape of battery production, quality control is paramount, especially in cylindrical battery pilot line operations. As demand for high-quality batteries continues to rise, organizations must establish stringent quality assurance protocols that monitor every step of the manufacturing process. Implementing advanced inspection technologies, such as automated optical inspection and real-time data analytics, can significantly enhance the detection of defects early in production cycles. By adopting these best practices, companies can not only ensure the durability and reliability of their batteries but also reduce waste and improve overall efficiency.

Furthermore, fostering a culture of continuous improvement within pilot line operations is vital. Training employees on the latest quality control techniques and encouraging feedback can lead to innovative solutions that address production challenges. Harnessing the power of collaboration between different teams, including engineering, production, and quality assurance, will create a more cohesive approach to problem-solving. In an era where battery production faces both challenges and opportunities, prioritizing quality control will be essential for sustaining growth and meeting the increasing demands of the electric vehicle market.

Upgrading to advanced 32140 battery production equipment can yield significant cost savings and efficiency improvements. Conducting a thorough cost-benefit analysis is crucial for manufacturers considering this transition. Initially, the investment in new machinery may seem substantial; however, the long-term benefits often outweigh these upfront costs. Enhanced automation and precision of advanced equipment can lead to reduced waste and lower labor costs, creating a more efficient production process. By improving yield rates, companies can also capitalize on higher profit margins as production scales up.

Moreover, the integration of cutting-edge technology such as smart manufacturing systems can further optimize the workflow. Real-time monitoring and data analytics tools enable better decision-making and predictive maintenance, minimizing downtime and extending equipment lifespan. Additionally, the growing demand for cylindrical batteries in various industries highlights the importance of staying competitive. Upgrading to a highly efficient 32140 pilot line not only enhances production capabilities but also positions companies favorably within the market, ensuring they can respond swiftly to evolving consumer needs and trends.