Leave Your Message

In the fast-paced world of manufacturing, maintaining high standards while maximizing efficiency is crucial, especially in processes like Ab Core Tab Welding. This essential technique not only impacts the structural integrity of products but also plays a significant role in overall production timelines. As manufacturers strive to enhance quality and reduce costs, having an effective checklist for Ab Core Tab Welding becomes paramount.

This ultimate guide aims to provide industry professionals with a comprehensive framework to boost both the quality and efficiency of their welding operations. By following these key guidelines, you can ensure that your Ab Core Tab Welding processes are optimized, leading to better outcomes and increased competitiveness in the market.

Whether you are a seasoned expert or new to this specialized field, understanding the nuances of this process will empower you to achieve excellence in manufacturing.

In the realm of manufacturing, particularly in processes like Ab core tab welding, assessing quality requires a meticulous approach. Key metrics such as weld strength, consistency, and defect detection must be prioritized to enhance overall efficiency. Recently, the application of advanced technologies like deep convolutional networks has shown promise in defect detection, especially in multi-layer welded structures. By implementing such innovations, manufacturers can reliably identify weaknesses in welds before they lead to larger issues in production.

Another vital aspect of assessing welding quality is real-time data management. Tools that provide instantaneous feedback on the welding process, akin to new welding information management systems, allow for immediate adjustments and improvements. Incorporating predictive quality models, drawn from digital twin technology, can also offer insights into potential defects, further refining the elbow grease needed to ensure quality. In essence, focusing on these metrics not only boosts the performance of Ab core tab welding but also fortifies the integrity of the entire manufacturing workflow.

Temperature control plays a crucial role in the efficiency of welding processes, particularly when it comes to ab core tab welding. Maintaining the optimal temperature can significantly influence the quality of welds, ensuring strong bonds and minimizing defects.

When welding materials, the thermal conditions under which the process occurs can determine the overall structural integrity. If the temperature is too low, the welds may become brittle, while excessive heat can lead to warping and material degradation.

In incorporating advanced temperature control technologies, not only enhances welding performance but also contributes to improved manufacturing efficiency. By employing thermostats, infrared sensors, or other monitoring systems, manufacturers can achieve precise temperature management. This leads to consistent welding results and reduces the likelihood of rework or scrap caused by poor weld quality.

Ultimately, efficient temperature control fosters a more reliable production environment, allowing manufacturers to meet stringent quality standards while optimizing resource use.

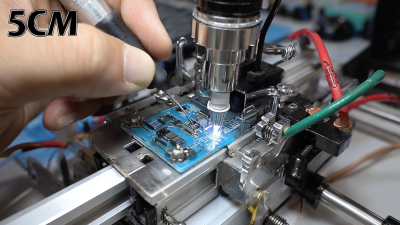

In the realm of manufacturing, especially with the rise of electric vehicle production, the importance of

tab welding cannot be overstated. Aluminum laser welding, particularly for alloys like 1100, is widely utilized in battery cell manufacturing.

However, this technique is not without its challenges. One common defect that can arise is

hydrogen porosity, which significantly affects the quality and integrity of welding joints. A recent study highlighted that controlling the formation of hydrogen porosity is crucial for achieving optimal weld performance and ensuring reliability in high-stakes applications.

To mitigate these defects, implementing strict quality control measures is essential. Conducting regular inspections and utilizing advanced modeling techniques can help in predicting and preventing

hydrogen porosity during the welding process. Operators should be trained on the importance of controlling environmental conditions, as moisture can contribute to hydrogen generation.

Tips:

1. Ensure that the welding area is free from moisture and contaminants to reduce the risk of hydrogen porosity.

2. Regularly calibrate and test equipment to maintain consistent performance, which is vital in preventing common welding defects.

3. Employ real-time monitoring systems that can detect anomalies during the welding process and allow for immediate corrective actions.

By proactively addressing these common defects, manufacturers can significantly enhance both the quality and efficiency of their

tab welding processes.

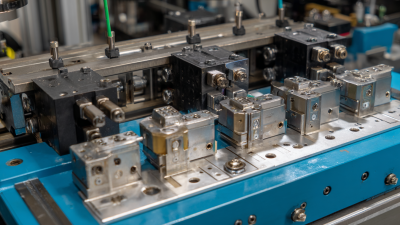

When it comes to optimal Ab Core Tab welding, having the right tools and technologies at your disposal is paramount for both quality and efficiency. Essential tools include precision welding machines that are capable of delivering consistent heat and weld penetration. These machines should be equipped with programmable features that allow for adjustments based on the material thickness and type, ensuring a flawless weld every time. Additionally, using high-quality tab materials that are compatible with your welding technology can significantly enhance the strength and durability of the welds.

Modern advancements in technology have also introduced various automation solutions into the welding process. Robotic welding arms, for example, not only increase production speed but also reduce human error, which can compromise weld quality. Incorporating laser alignment systems can further enhance precision by ensuring that tabs are positioned correctly before welding. Furthermore, investing in monitoring systems that track weld parameters in real-time can provide valuable feedback, allowing manufacturers to make necessary adjustments instantly, resulting in fewer defects and higher-quality outputs. Utilizing these essential tools and technologies can dramatically improve the overall performance of Ab Core Tab welding in manufacturing.

In today’s manufacturing landscape, leveraging data-driven strategies is crucial for enhancing production line efficiency and quality. Recent studies indicate that companies employing data analytics can improve their operational efficiency by up to 30%. By utilizing real-time monitoring systems, manufacturers can identify bottlenecks in the welding process and reduce cycle times significantly. For example, predictive maintenance analytics can prevent equipment failures by up to 70% by analyzing machine performance data to schedule maintenance proactively.

Additionally, integrating quality management systems with data analytics offers a dual benefit: not only can it streamline production processes, but it can also enhance the quality of outputs. According to a report by the International Journal of Advanced Manufacturing Technology, manufacturers that implemented data-driven quality control mechanisms saw a reduction in defect rates by an impressive 40%. By analyzing data trends and implementing corrective actions, organizations can produce higher quality products while maintaining efficiency. The synergy of data analytics in welding processes not only optimizes workflows but also elevates the overall manufacturing standards.

| Dimension | Data Value |

|---|---|

| Welding Temperature (°C) | 180 |

| Welding Speed (mm/s) | 200 |

| Material Thickness (mm) | 3 |

| Weld Length (mm) | 150 |

| Defect Rate (%) | 2 |

| Production Downtime (hrs/week) | 5 |

| Cycle Time (seconds) | 30 |

| Operator Training Hours (hours) | 10 |