Leave Your Message

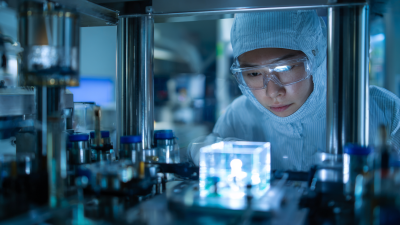

As industries increasingly prioritize efficiency and safety in controlled environments, the Single-Station Series Vacuum Glove Box has emerged as a pivotal tool for laboratory and manufacturing operations. According to a recent report from the National Institute of Standards and Technology, streamlining workflows can enhance productivity by up to 30%, making it essential for organizations to adopt advanced technologies like the Single-Station Series Vacuum Glove Box. This innovative system not only minimizes contamination risks but also maximizes user dexterity and operational agility within hazard-free settings. By implementing top strategies tailored for this versatile equipment, companies can significantly boost their operational effectiveness and maintain high standards of quality and safety.

This blog will explore key approaches to exploit the full potential of the Single-Station Series Vacuum Glove Box, enabling teams to achieve remarkable efficiency gains.

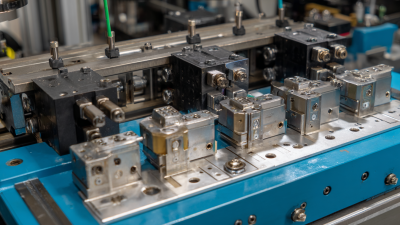

Setting up a Single-Station Series Vacuum Glove Box requires careful consideration to optimize its efficiency and effectiveness. According to a recent industry report by Research and Markets, the glove box market is expected to witness a CAGR of 6.2% through 2027, demonstrating the growing reliance on such equipment for sensitive material handling. To ensure that your glove box operates at peak efficiency, it’s essential to properly configure and maintain the system.

Tip 1: Proper Seal Maintenance - One of the most critical aspects of setting up your glove box is ensuring that seals are adequately maintained. Regularly inspect the integrity of the seals and replace them when necessary to avoid contamination. Studies have shown that maintaining an airtight environment can improve sample integrity by up to 95%.

Tip 2: Optimize Work Environment - Position the glove box in a controlled environment, ideally with stable temperature and humidity levels. This not only enhances the performance of the equipment but also prolongs its lifespan. Data from an environmental assessment suggested that keeping the workspace within ±2°C and 40-60% relative humidity can reduce equipment wear and improve operational efficiency.

Incorporating these best practices will not only streamline your operations but also significantly enhance the overall performance of your Single-Station Series Vacuum Glove Box.

To ensure the longevity and optimal performance of your Single-Station Series Vacuum Glove Box, regular maintenance is essential. Start by routinely checking the seals and gaskets for any signs of wear or damage. These components are crucial for maintaining the vacuum environment; even minuscule leaks can compromise the integrity of your processes. It's advisable to clean the glove ports and inner surfaces with suitable solvents to prevent contamination, which can affect the quality of your work.

Another key maintenance aspect involves the vacuum pump. Regularly inspect the pump for any unusual noises or vibrations that could indicate issues. Change the oil according to the manufacturer's guidelines to maintain efficient operation and reduce the risk of failures. Additionally, monitor the vacuum levels consistently; fluctuations may signal a need for servicing. By establishing a scheduled maintenance routine, you will not only enhance the performance of the glove box but also extend its lifespan, allowing for more efficient and reliable operations in your lab environment.

In optimizing workflow within a single-station vacuum glove box, organization is key. A well-organized workspace not only boosts efficiency but also minimizes the risk of errors during delicate procedures. By systematically categorizing tools and materials, operators can easily access what they need, saving valuable time. Establishing designated areas for specific tasks will help in maintaining focus and reducing distractions, ultimately enhancing productivity.

**Tips for Effective Workspace Organization:**

1. **Label Everything**: Clearly labeling shelves and containers helps in quickly locating items without unnecessary searching. This simple practice can significantly cut down on time spent looking for tools and materials.

2. **Utilize Vertical Space**: Make the most of the glove box’s vertical space by installing shelves or hooks. This not only keeps the work surface clear but also allows for more efficient use of limited area.

3. **Regular Clean-Up**: Implementing a routine for cleaning and reorganizing the workspace ensures that it remains efficient. A clutter-free environment promotes clear thinking and aids in smoother operational flow.

By focusing on workspace organization, users of the single-station vacuum glove box can maximize their efficiency and streamline their processes effectively.

| Strategy | Description | Benefits | Implementation Steps |

|---|---|---|---|

| Workspace Organization | Arranging tools and materials for easy access and flow. | Reduces time spent searching for items; increases productivity. | Analyze workflow; categorize tools; establish designated spaces. |

| Standard Operating Procedures | Creating clear guidelines for each process. | Ensures consistency; minimizes errors; facilitates training. | Draft procedures; review and refine; distribute to team. |

| Regular Maintenance Checks | Performing routine inspections and maintenance of equipment. | Prevents downtime; extends equipment life; improves safety. | Schedule checks; document findings; address issues promptly. |

| Time Management Tools | Using software or tools to track and plan tasks. | Enhances focus; prioritizes tasks; tracks progress. | Research tools; train team; integrate into daily routines. |

Efficient operation of a single-station series vacuum glove box is crucial for laboratories handling sensitive materials. One of the common challenges faced by users is maintaining an optimal vacuum environment, which can be disrupted by improper sealing or contamination.

According to a recent study, up to 30% of lab time can be wasted due to the need for repeated cleaning and re-establishing vacuum conditions. To combat this, implementing routine maintenance checks and regular calibration of the vacuum system is essential. Adopting these practices can enhance the longevity of the equipment and minimize downtime significantly.

Another frequent issue is the manipulation of samples within the glove box, which can lead to operator fatigue and decreased productivity. Ergonomics plays a crucial role here; by utilizing adjustable work surfaces and strategically placing tools within easy reach, users can streamline their workflows. A survey from the Laboratory Equipment Manufacturers Association indicates that labs adopting ergonomic solutions reported a 25% increase in operational efficiency. By addressing these challenges with proactive strategies, labs can maximize the effectiveness of their vacuum glove boxes and achieve more reliable outcomes in their experiments.

The advent of advanced technology in the field of vacuum glove boxes has revolutionized the way we conduct sensitive experiments. The Single-Station Series Vacuum Glove Box, in particular, benefits significantly from an array of accessories and software that enhance its precision and operational efficiency. Utilizing innovative accessories like integrated pressure gauges and specialized glove materials can provide real-time feedback and reduce contamination risks, ensuring that samples remain uncontaminated throughout the experimental process.

Moreover, leveraging software solutions tailored for vacuum glove boxes brings another layer of sophistication to laboratory operations. These software programs can monitor and control environmental conditions, track variables such as temperature and humidity, and even automate data logging for seamless record-keeping. By marrying hardware enhancements with cutting-edge software, researchers can create a harmonious working environment that not only maximizes productivity but also guarantees the integrity of their findings. This synergy between technology and laboratory equipment is essential for pushing the boundaries of research and innovation in today's scientific landscape.