Leave Your Message

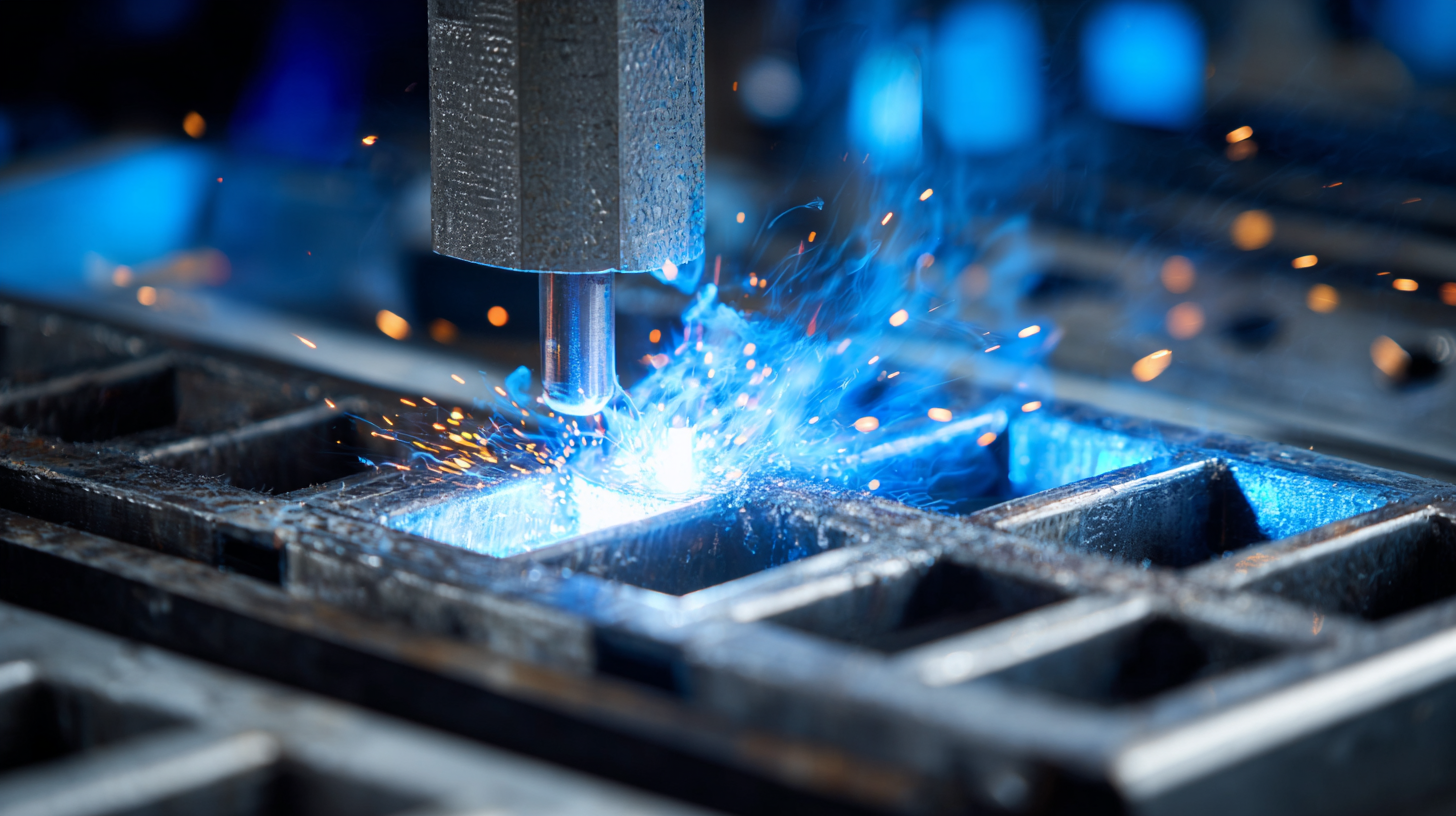

In the realm of structural engineering, the significance of welding techniques cannot be overstated, particularly in critical applications where integrity is paramount. Among these techniques, "Ab Core Tab Welding" has emerged as a vital process, noted for its ability to enhance the structural performance of composite materials. According to the American Welding Society, nearly 30% of structural failures in critical components can be traced back to inadequate welding practices, underscoring the necessity for mastery in this area. A recent study highlighted that projects utilizing advanced welding methodologies, such as Ab Core Tab Welding, saw a 25% reduction in stress-related failures. This blog aims to delve into the intricacies of Ab Core Tab Welding, offering insights and techniques to master this essential skill, ultimately contributing to safer and more reliable structures in various industries.

Ab Core Tab Welding is a vital technique in the construction and manufacturing industries, emphasizing not only precision but also the structural integrity of the final product. Understanding the fundamentals of this process begins with recognizing the role of tab welds in providing additional support to core structures. This specialized welding method enhances load distribution, thereby reducing the risk of joint failure and extending the lifespan of the assembly.

Ab Core Tab Welding is a vital technique in the construction and manufacturing industries, emphasizing not only precision but also the structural integrity of the final product. Understanding the fundamentals of this process begins with recognizing the role of tab welds in providing additional support to core structures. This specialized welding method enhances load distribution, thereby reducing the risk of joint failure and extending the lifespan of the assembly.

Mastering Ab Core Tab Welding requires familiarity with various welding techniques and materials. It’s essential to select the appropriate welding equipment and settings to achieve the desired penetration and fusion of materials. Additionally, knowledge of metallurgical properties plays a crucial role, as it influences how different metals react under heat and stress. By honing these skills, welders can significantly improve the strength and reliability of the structures, ensuring they meet both safety standards and performance expectations.

Emphasizing the importance of training and practice, professionals who invest time in mastering this technique will likely see substantial improvements in their work quality and structural outcomes.

When it comes to mastering Ab Core Tab welding, having the right tools and equipment is essential to achieving enhanced structural integrity. The primary tools required include a TIG welding machine, customized fixtures, and high-quality filler rods that cater to the specific materials being joined. According to the American Welding Society, 30% of structural failures can be attributed to inadequate welding techniques, underscoring the importance of utilizing proper equipment to prevent costly mistakes.

Ensure your workspace is properly set up with adequate ventilation and safety gear. A reliable welding helmet, gloves, and an apron made from flame-resistant materials are crucial for safety during the welding process. Moreover, maintain your tools by regularly inspecting for wear and tear; this practice can decrease the likelihood of equipment malfunction, which statistics show can delay project timelines by up to 25%.

Tip: Before starting any welding task, perform a test weld on scrap material to adjust the machine settings. This step can help identify the optimal parameters for heat and speed, resulting in cleaner welds. Additionally, invest in a high-quality digital caliper to measure weld bead thickness, ensuring consistency and precision in your projects.

| Tool/Equipment | Use | Specifications | Maintenance Tips |

|---|---|---|---|

| TIG Welder | Precision welding of thin materials | AC/DC capability, 200 amp output | Clean the torch regularly, check gas flow |

| Fume Extractor | Removes harmful fumes | High efficiency particulate air (HEPA) filter | Replace filters as recommended, check motor functions |

| Welding Helmet | Protect eyes from sparks and UV | Auto-darkening, ANSI Z87.1 compliant | Check battery, clean the lens regularly |

| Clamps | Secure materials during welding | Variety of sizes, up to 2000 lbs clamping force | Inspect for wear, store in dry place |

| Measuring Tools | Ensure accurate dimensions | Calipers, tape measures | Keep calibrated, protect from damage |

Mastering Ab Core Tab Welding is essential for professionals aiming to enhance structural integrity across various applications. This technique not only improves the weld integrity but also contributes to overall project durability. According to industry reports, effective tab welding can increase the fatigue life of structures by up to 30%. To achieve mastery in this technique, precision and practice are key.

A step-by-step approach to mastering Ab Core Tab Welding involves understanding the fundamental principles of welding, choosing the right materials, and implementing correct heat settings. Recent advancements in educational methodologies, such as the incorporation of virtual reality (VR) technology into welding training, are revolutionizing skill development. Research indicates that trainees using VR can increase their welding efficiency by 25% due to immersive simulations that mimic real-world scenarios. By embracing these modern training tools alongside traditional methods, welders can significantly enhance their skills and ensure the reliability of their welds.

When it comes to mastering Ab Core Tab welding, understanding common mistakes can significantly enhance structural integrity. Research indicates that over 30% of weld failures in structural applications are attributed to improper technique and lack of awareness of critical factors. One prevalent mistake is inadequate surface preparation; studies show that contaminants can reduce weld strength by up to 50%. To mitigate this risk, ensure surfaces are clean, dry, and free from oxidation or oil before welding.

Another common error involves incorrect heat settings. Insufficient heat can lead to incomplete penetration, while excessive heat may result in burn-through or warping. Industry data suggests that employing the right heat settings can improve weld quality by 20-30%, harnessing the full potential of the materials used. Employing advanced welding technology and real-time monitoring systems can help in maintaining optimal conditions, thus avoiding these critical pitfalls. By focusing on these aspects, welders can not only prevent common issues but also achieve a higher level of performance in their projects.

Ab core tab welding is an essential technique for enhancing the structural integrity of welded components. To improve the quality of your welds, it’s crucial to focus on the preparation of both the base materials and the welding environment. Ensure that the surfaces to be welded are clean and free from contaminants, as even minor impurities can compromise the bond. Additionally, controlling the temperature and humidity levels during the welding process can prevent distortion and ensure a more uniform heat distribution, leading to stronger joints.

Another advanced tip is to utilize proper welding techniques that suit the specific materials and thicknesses you are working with. The choice of welding parameters, such as the welding speed and voltage, directly impacts the penetration and fusion of the weld. Experimenting with different filler materials can also significantly affect the mechanical properties of the finished weld. Don’t forget to implement post-weld treatments, such as stress relieving and inspections, as these steps are crucial for identifying potential weaknesses and ensuring the overall durability of the structure.