Leave Your Message

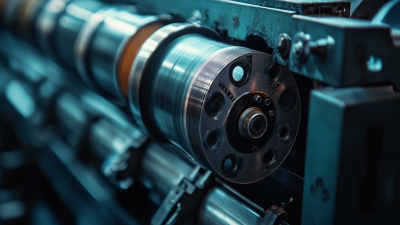

In the realm of modern manufacturing, the precision of welding techniques plays a pivotal role in enhancing product quality and operational efficiency. A notable advancement in this field is the Ab Core Tab Welding process, which has been demonstrated to reduce defects by up to 30% compared to traditional methods, according to a recent industry report by the Welding Institute. This innovative technology focuses on applying meticulous control over key parameters, thus ensuring stronger and more reliable joints in complex assemblies.

With increasing demands for high-performance materials, manufacturers are turning to Ab Core Tab Welding not only to meet stringent quality standards but also to optimize production cycles and reduce costs. As industries continue to embrace automation and precision engineering, understanding and implementing the benefits of Ab Core Tab Welding becomes essential for maintaining competitive advantage in a rapidly evolving market.

Precision in Ab Core tab welding processes plays a pivotal role in modern manufacturing, yielding a multitude of benefits that significantly enhance overall productivity and product quality. According to a report by the International Institute of Welding, improvements in welding accuracy can reduce defect rates by up to 30%, leading to substantial cost savings for manufacturers. These enhancements not only streamline the production line but also minimize the need for rework, which can account for 20% of total manufacturing costs.

Moreover, enhanced accuracy in welding processes contributes to better structural integrity of welded components, which is critical in industries such as automotive and aerospace. A study from the American Welding Society indicates that components with higher weld precision exhibit improved fatigue resistance and durability, reducing the likelihood of mechanical failures. This increased reliability translates into higher customer satisfaction and a competitive edge in the market, as companies can assure clients of the robustness and longevity of their products. The advancement of technology in Ab Core tab welding, therefore, not only fosters efficiency but also aligns with stringent industry standards, ultimately reshaping the landscape of modern manufacturing.

Precision welding has emerged as a game-changer in modern manufacturing, especially in the context of Ab Core Tab Welding. The impact of precision welding on product quality cannot be overstated, as it significantly enhances the structural integrity of welded components. By utilizing advanced technologies and meticulous techniques, manufacturers can achieve tighter tolerances and more uniform welds. This ensures that the final products not only meet stringent design specifications but also exhibit higher durability and reliability during operation.

In addition to quality improvements, precision welding also boosts consistency across production batches. With automated welding processes, variations that often arise from manual techniques can be minimized, resulting in products that are virtually identical in terms of performance and aesthetics. This consistency is crucial for industries that require exhaustive quality assurance measures, as it reduces the risk of defects and increases customer satisfaction. Ultimately, the advantages of precision welding pave the way for manufacturers to deliver superior products that stand out in today's competitive market.

| Parameter | Measurement | Impact | Importance |

|---|---|---|---|

| Weld Accuracy | ±0.02 mm | Reduces misalignment | High |

| Tensile Strength | 350 MPa | Enhances durability | Critical |

| Weld Completion Rate | 98% | Minimizes rework | High |

| Heat Affected Zone | < 1 mm | Minimizes distortion | Medium |

| Cost Efficiency | 15% reduction | Improves profit margins | High |

Precision in ab core tab welding is revolutionizing modern manufacturing by delivering significant cost efficiency. The intricacies involved in this welding technique allow for minimized material waste and enhanced durability in finished products. By employing precision welding, manufacturers can produce components that not only meet stringent quality standards but also reduce the likelihood of defects. This accuracy results in lower costs associated with rework and repairs, ultimately driving down production expenses.

Additionally, precision in manufacturing facilitates streamlined processes, thereby optimizing resource allocation. Automated systems that promote precise tab welding can significantly increase throughput while maintaining high levels of quality control. With reduced cycle times and enhanced operational efficiency, companies can respond more swiftly to market demands. This agility not only supports better inventory management but also contributes to overall financial savings, making precision a key factor in driving profitability and competitiveness in the modern manufacturing landscape.

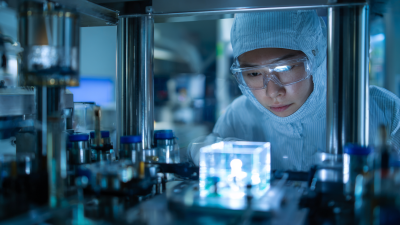

The landscape of modern manufacturing is being transformed by technological innovations that enhance precision in Ab core tab welding. According to a report by MarketsandMarkets, the global welding equipment market is projected to grow from $16.49 billion in 2020 to $23.37 billion by 2025, highlighting the increasing importance of advanced welding technologies.

In particular, developments in laser welding systems have driven a significant uptick in accuracy, reducing weld defects by up to 50% compared to traditional methods. This leap in technology not only improves product quality but also enhances production efficiency, allowing manufacturers to meet tighter tolerances demanded by today's market.

Furthermore, the integration of artificial intelligence and machine learning in welding processes is revolutionizing quality control. A study published in the International Journal of Advanced Manufacturing Technology reveals that AI-driven monitoring systems can detect anomalies during the welding process in real-time, decreasing rework costs by as much as 30%. These innovations are essential for manufacturers looking to remain competitive, as they facilitate a higher degree of customization and adaptability in production lines.

As these technologies continue to evolve, the benefits of precision in Ab core tab welding will undoubtedly play a pivotal role in shaping the future of the manufacturing industry.

The future of precision welding technology, particularly in the context of Ab core tab welding, promises to revolutionize modern manufacturing. As industries increasingly rely on automation and advanced materials, welding processes are also evolving to meet these demands. Innovations such as laser welding and robotic automation are being integrated into the production line, enabling manufacturers to achieve higher precision and improved quality in their welds. These advancements not only enhance operational efficiency but also minimize waste, leading to a more sustainable manufacturing environment.

Moreover, the implications of these trends extend beyond just technological improvements. The shift toward precision welding fosters a new skill set within the workforce, as operators need to be adept in using sophisticated machinery and interpreting complex data analytics for quality assurance. Industries such as automotive and aerospace will particularly benefit, as the demand for lightweight and strong materials increases. By focusing on precision, manufacturers can ensure that their products meet stringent safety and performance standards, ultimately driving competitive advantage in a fast-evolving market.