Leave Your Message

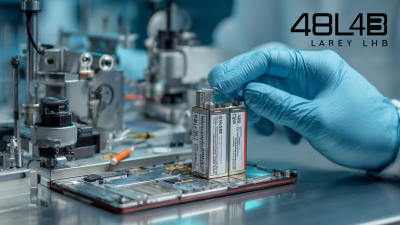

The 32140 Tabless Battery Pilot Line represents a significant advancement in battery technology. This innovative production method simplifies the design by eliminating tabs. As a result, the batteries become lighter and more efficient. This efficiency has broad implications for electric vehicles and renewable energy storage.

Introducing the 32140 Tabless Battery Pilot Line may enhance performance and safety. However, challenges remain in its implementation. Manufacturers need to adapt to this new approach. The potential cost implications also need careful consideration. It is crucial to reflect on how these innovations align with market demands.

Ultimately, the successes and failures of the 32140 Tabless Battery Pilot Line will shape the future of battery technology. Stakeholders must approach this evolution with both optimism and caution. Advancements are promising, yet the path to reliable production is complex.

The 32140 Tabless Battery Pilot Line represents a significant step in battery technology. This innovative line utilizes a unique design that eliminates conventional tabs. By doing so, it reduces manufacturing complexity. The tabless design also enhances efficiency during assembly. This change leads to cost savings and a smaller footprint.

In addition, the 32140 Tabless Battery offers improved performance. The absence of tabs means better energy distribution. This can enhance battery lifespan. However, challenges exist in scaling this technology for larger production. Companies must refine processes to ensure quality. There is a need for ongoing research and development to overcome potential hurdles.

While the benefits are promising, there are some areas requiring attention. The initial setup costs may be high. Not all manufacturing plants are ready for such changes. Training might be necessary for workers. In effect, there is a balance between innovation and practicality that needs to be addressed.

The 32140 Tabless Battery technology presents several key features that can revolutionize battery design. One major aspect is its tabless architecture, which eliminates the need for traditional tabs in cells. This design reduces manufacturing complexity while also improving energy density. According to a recent industry report, tabless cells can potentially achieve 20% more energy storage compared to conventional battery types.

Another important feature is the increased thermal stability. The tabless design allows for better heat dissipation. This can enhance safety by reducing the risk of overheating. A report by the International Energy Agency noted that thermal management is crucial for the longevity and efficiency of batteries, as overheating can lead to performance degradation.

Additionally, the 32140 Tabless Battery Pilot Line aims to streamline production. By simplifying the cell assembly process, manufacturers can reduce costs and time. It’s worth mentioning that while these advancements are promising, challenges remain. For instance, not all manufacturers may adapt quickly to this new technology. Some may struggle with transitioning their production lines. The industry is still navigating the balance between innovation and existing practices.

The 32140 Tabless Battery Pilot Line represents a significant innovation in battery technology. Its tabless design enhances energy density, allowing for more stored energy in less space. This saves weight and helps achieve lighter batteries for vehicles and electronic devices. The straightforward design reduces the number of components. Fewer components mean fewer points of failure.

The efficiency of this design is notable. It enables better thermal management, which can prolong battery life. Improved energy flow occurs throughout the cell, increasing overall performance. However, transitioning to this new technology poses challenges. It requires new manufacturing processes and equipment. This change can lead to higher initial investment and some technical hiccups.

While the benefits are clear, concerns remain. How will existing infrastructures adapt? Will production costs rise? Engineers should evaluate these factors critically. Continuous improvement is essential to maximize the advantages of tabless battery designs and ensure they meet future energy needs.

| Feature | Traditional Battery | Tabless Battery |

|---|---|---|

| Energy Density (Wh/kg) | 150 | 200 |

| Charge Time (hours) | 2.5 | 1.5 |

| Cycle Life (cycles) | 1000 | 1500 |

| Thermal Management | Moderate | Enhanced |

| Manufacturing Cost (%) | 100 | 95 |

The 32140 Tabless Battery Pilot Line is a significant innovation in battery technology. It aims to enhance production efficiency while reducing costs. This pilot line leverages a tabless design for batteries, which simplifies the manufacturing process. According to the latest industry reports, the pilot line can potentially lead to a 20% reduction in production costs.

The impact of the pilot line on scaling battery production is profound. The tabless design eliminates many complex connections. This can lower the likelihood of manufacturing defects, a persistent issue in traditional battery production. A recent analysis shows that manufacturers could achieve up to a 30% increase in battery throughput. However, operators must adapt to new processes, which may introduce initial challenges.

Moreover, the pilot line highlights the need for data-driven decisions in scaling. Proper monitoring is crucial to ensure efficiency gains translate into actual cost savings. Current data suggests that leading firms could save approximately $100 million in operational costs annually with optimized pilot lines. Yet, this potential must be approached cautiously. Continuous improvement and feedback loops are essential for long-term success.

The 32140 Tabless Battery Pilot Line represents a significant shift in battery design and production. This innovative approach eliminates traditional tabs, creating a more efficient energy flow. The new design optimizes space and increases energy density. This can lead to lighter and smaller battery packs. Such advancements are crucial for electric vehicles because they enhance performance and range.

Future implications for electric vehicles are vast. Increased battery efficiency could reduce costs, making EVs more accessible to consumers. Furthermore, these batteries could offer faster charging times. This is a potential game changer for urban mobility and long-distance travel. Renewable energy storage solutions also benefit. Improved battery technology could store more energy from solar and wind sources. This helps balance supply and demand effectively.

While the potential is exciting, challenges remain. Manufacturing at scale is complex and resource-intensive. There may be environmental concerns tied to material sourcing. Stakeholders must consider these factors seriously. Thoughtful strategies are necessary to ensure sustainable growth in this emerging sector. Each step forward requires careful reflection on broader implications.