Leave Your Message

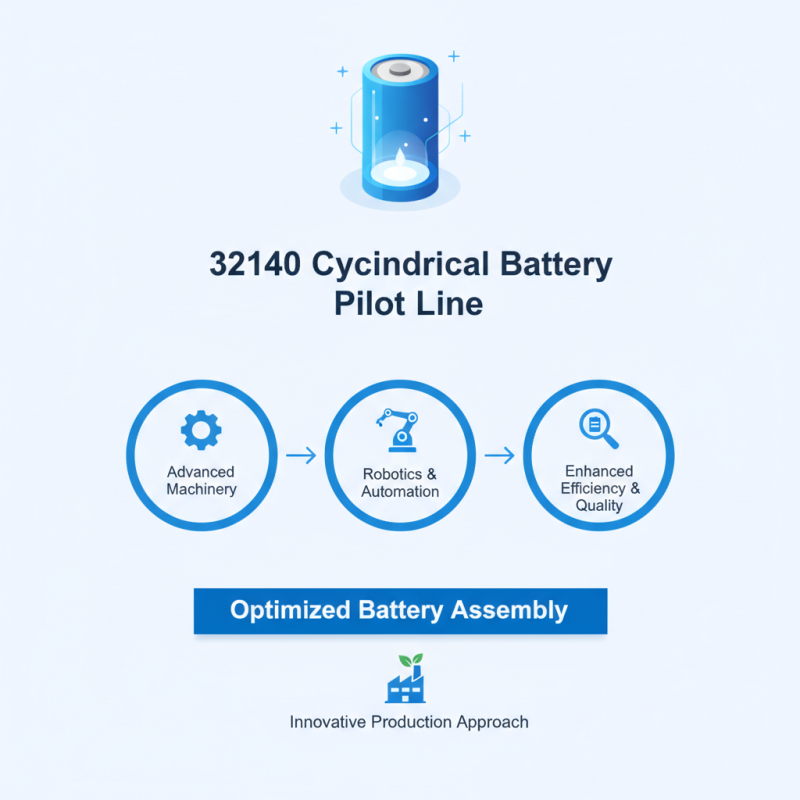

The "32140 Cylindrical Battery Pilot Line" is an innovative advancement in battery production technology. According to a recent market report by BloombergNEF, cylindrical batteries are projected to dominate the market, accounting for over 40% of the global battery supply by 2025. Experts believe that the 32140 format is key to achieving higher energy density and efficiency. Dr. Emily Chen, a leading expert in battery technology, states, "The 32140 design offers a unique balance of size and power output, crucial for future applications."

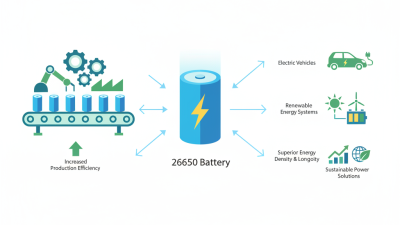

As the demand for electric vehicles and renewable energy storage rises, the 32140 Cylindrical Battery Pilot Line meets these challenges head-on. This pilot line represents a shift towards more sustainable manufacturing practices, yet it is not without its flaws. The initial cost and scalability of the line raise critical questions. The industry seeks breakthroughs in production efficiency to maximize the benefits of this promising technology. Continuous improvement and adaptation will be necessary to overcome obstacles.

In summary, while the 32140 Cylindrical Battery Pilot Line holds great potential, the journey ahead requires careful navigation. Flexibility and innovation will dictate success in this rapidly evolving landscape.

The 32140 cylindrical battery technology represents an exciting advancement in power storage. This type of battery is designed for high capacity and efficiency. Its cylindrical shape allows for better packing and heat dissipation. This design helps in many applications, from electric vehicles to portable devices.

Tips: Consider the benefits of this shape. It can lead to improved performance in high-drain scenarios. Also, the cylindrical design aids in recycling efforts.

Moreover, the technology behind the 32140 batteries is continuously evolving. Researchers are focusing on enhancing lifespan and charging speeds. However, challenges remain in balancing energy density and cost. This may lead to higher prices initially, prompting users to think critically about their energy needs.

Tips: Monitor the advancements in battery tech. Users may find opportunities for innovation and savings. Staying informed is key to making wise choices.

The 32140 cylindrical batteries open pathways for future developments. Their potential impact on sustainability cannot be ignored. As this technology matures, exploring its benefits and drawbacks becomes essential for consumers and manufacturers alike.

The 32140 cylindrical battery pilot line represents an innovative approach to battery production. This line is designed to enhance efficiency and quality in manufacturing. Key components of this pilot line include advanced machinery, robotics, and automation systems. These technologies work together to optimize each stage of battery assembly.

Robotic arms handle the cells with precision, minimizing the risk of damage. The automation system monitors the entire process, ensuring consistency and reliability. However, challenges do arise. For instance, maintaining the calibration of these machines can be complicated. Anomalies in production may require immediate adjustments, which can disrupt the workflow.

Quality control remains a priority throughout the manufacturing process. Engineers regularly evaluate the performance of each component. Issues like battery uniformity and energy density must be assessed meticulously. Sometimes, slight variations in the raw materials lead to unexpected results. Continuous feedback in the pilot line is crucial for improvement. The goal is to refine the production techniques continuously and address any shortcomings promptly.

The production of 32140 cylindrical batteries involves intricate manufacturing processes. These processes begin with raw material selection, which typically includes high-purity lithium and nickel. Reports indicate that quality of these materials hugely impacts battery performance. Each material enhances energy density, stability, and lifespan.

The next manufacturing step is cell assembly. Automated systems are widely used for precision. However, technical glitches can result in inconsistencies. Manufacturers often face challenges in maintaining efficiency. Reports show that up to 15% of production may be deemed substandard due to minor defects. State-of-the-art equipment can reduce this rate significantly, but budget constraints often impact upgrades.

Tips: Regular training for staff is essential. It reduces human error and boosts overall quality. Implementing robust testing protocols can improve yield rates. Involving engineering teams early in the design phase can prevent costly mistakes and rework. These measures not only enhance productivity but also ensure better product uniformity.

| Process Stage | Description | Key Technologies | Quality Control Measures |

|---|---|---|---|

| Material Preparation | Sourcing and processing of raw materials for battery components. | High-purity chemical synthesis, Material characterization. | Material testing protocols, Traceability systems. |

| Electrode Manufacturing | Coating and drying of electrodes to produce anodes and cathodes. | Roll-to-roll coating technology, Drying ovens. | Thickness measurement, Surface inspection. |

| Cell Assembly | Assembling electrodes, separators, and electrolytes into cells. | Robotic assembly lines, Automated handling systems. | Alignment checks, Cell integrity testing. |

| Formation & Aging | Initial charging of cells followed by a stability period. | Battery management systems, Environmental control chambers. | Capacity testing, Electrochemical impedance spectroscopy. |

| Final Testing | Comprehensive testing to ensure performance meets specifications. | Automated testing rigs, Data analytics tools. | Endurance testing, Safety validation procedures. |

The 32140 cylindrical battery represents a significant advancement in energy storage technology. These batteries offer high energy density, making them suitable for electric vehicles and portable electronics. Their cylindrical design maximizes space efficiency. This feature allows for better integration into various devices. The smart construction ensures uniform energy distribution, enhancing performance.

One of the main advantages is their thermal management. The cylindrical shape helps dissipate heat effectively, minimizing the risk of overheating. This aspect is crucial for applications where safety is paramount. Additionally, 32140 batteries are compatible with fast-charging systems. They can quickly recharge without compromising battery lifespan. This characteristic attracts developers and manufacturers in the tech industry.

However, challenges exist. The manufacturing process is complex and requires precise engineering. Inconsistent production can lead to quality issues. Furthermore, there’s ongoing debate about recycling methods for these batteries. Innovative solutions are needed to address environmental concerns. As the demand for clean energy solutions grows, so does the pressure to improve these technologies. The potential is vast, but careful consideration is necessary.

The 32140 cylindrical battery technology is rapidly evolving. This battery format is gaining attention for its promising energy density and efficiency. Reports indicate that these batteries can reach over 200 Wh/kg, making them suitable for various applications. However, the technology is still in its infancy stage. The move towards larger capacities is essential for meeting modern energy needs.

Future trends suggest a significant focus on optimizing production processes. Innovations in electrode materials and chemistries are expected to boost performance. Industry analysts project that the demand for higher-capacity batteries will grow by 30% by 2025. This rapid growth indicates a pressing need for pilot line technologies, which allow for efficient scaling. Companies will need to balance cost with performance improvements, which is not an easy task.

Recycling and sustainability also present challenges. While advancements are being made, many processes remain inefficient. This highlights the importance of developing a circular economy for battery materials. A 2022 report estimated that nearly 40% of battery materials are underutilized. Ongoing research is necessary to refine these systems and ensure they meet future energy demands.