Leave Your Message

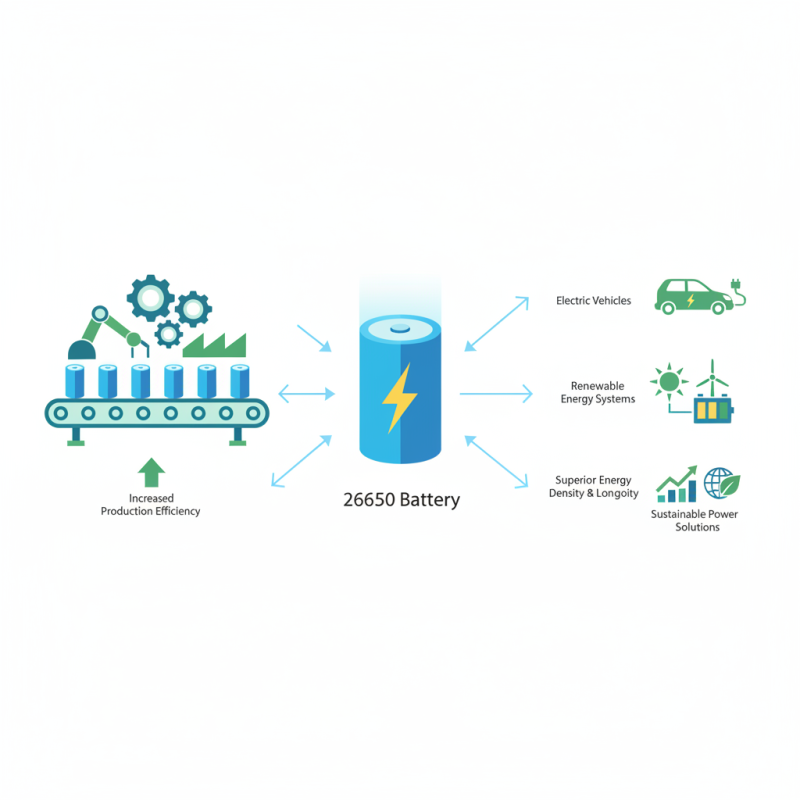

The development of the 26650 cylindrical battery pilot line represents a significant leap forward in energy storage technology, offering vast potential for various applications, including electric vehicles and renewable energy systems. According to a recent study by the International Energy Agency (IEA), the demand for advanced battery technologies is projected to increase by over 25% annually, underscoring the necessity for efficient manufacturing processes. The 26650 cylindrical battery, known for its superior energy density and longevity, is positioned to meet this growing demand, providing both consumers and industries with reliable and sustainable power solutions.

Dr. Mark Williams, a leading expert in battery technology, states, "The 26650 cylindrical battery pilot line is crucial for scaling production capabilities while maintaining quality control." This sentiment is echoed in numerous industry reports highlighting the importance of pilot lines in the rapid development and deployment of cutting-edge battery technology. By streamlining production processes and enhancing performance metrics, the 26650 cylindrical battery pilot line not only boosts efficiency but also fosters innovation in battery design and application. As the transition to electrification accelerates globally, the strategic implementation of pilot lines becomes paramount for meeting future energy needs.

The 26650 cylindrical battery pilot line represents a significant advancement in battery manufacturing technology, capitalizing on the unique design of the 26650 cell format. This specific size, measuring 26mm in diameter and 65mm in height, is gaining traction in industries such as renewable energy storage and electric vehicles, where higher energy density and longer cycle life are critical. According to industry reports, the global lithium-ion battery market is expected to exceed $100 billion by 2025, with cylindrical batteries contributing a substantial portion due to their robustness and enhanced thermal performance.

One of the key benefits of establishing a pilot line for 26650 batteries is the ability to streamline production processes and improve quality control. Pilot lines serve as a testing ground, allowing manufacturers to experiment with different materials and assembly techniques before scaling up to full production. This flexibility reduces the risk of defects and enhances battery performance, which is crucial in applications demanding reliability. Data from the Battery Innovation Center suggests that pilot production can lead to a 20% reduction in manufacturing costs while improving energy efficiency by 15%.

Tips: When considering implementing a pilot line, organizations should focus on developing strong partnerships with material suppliers and technology providers. Moreover, regular training and upskilling of the workforce can foster innovation, driving improvements in both efficiency and product quality. Another vital consideration is to stay updated with emerging technologies that could further enhance the capabilities of 26650 battery cells.

The manufacturing processes in the 26650 battery pilot line involve several key steps that ensure the production of high-quality cylindrical batteries. First, the preparation of electrode materials is crucial. This step includes blending active materials with conductors and binders to create a uniform slurry. The mixture is then coated onto metallic foils, which serve as the current collectors, before being dried to remove any solvents. This precise preparation is essential for optimizing the electrochemical performance of the finished battery.

Next is the cell assembly process, where the coated electrodes are cut into sheets and stacked, wound, or laminated, depending on the design. Separators are placed between the layers to prevent short circuits while allowing ionic movement. The assembly is then inserted into cylindrical casings that will contain the electrolyte. Following this, the filling process involves adding the electrolyte to the cells. This critical step must be performed under controlled conditions to avoid contamination and ensure proper function.

Finally, the electrochemical formation is carried out, where the cells undergo initial charging and discharging cycles. This helps to stabilize the electrolyte and enhance the performance of the battery. The pilot line's automated and precise processes not only improve efficiency but also ensure consistency across batches, significantly reducing quality variations and enhancing overall reliability in applications.

| Key Dimension | Description | Value |

|---|---|---|

| Battery Size | Diameter and Height | 26mm x 65mm |

| Nominal Voltage | Typical operating voltage per cell | 3.7V |

| Capacity | Total energy storage measurement | 3000mAh - 5000mAh |

| Cycle Life | Number of charge/discharge cycles until capacity drops to 80% | > 800 cycles |

| Charging Current | Recommended current for optimal charging | 1C (3000mA - 5000mA) |

| Discharge Current | Maximum current discharge capability | 10C (30A - 50A) |

| Chemistry | Type of battery chemistry used | Li-ion / LiFePO4 |

| Applications | Common uses of 26650 batteries | Power tools, Electric vehicles, Energy storage |

| Key Benefit | Advantages of using 26650 batteries | High capacity, Longer cycle life, Robust performance |

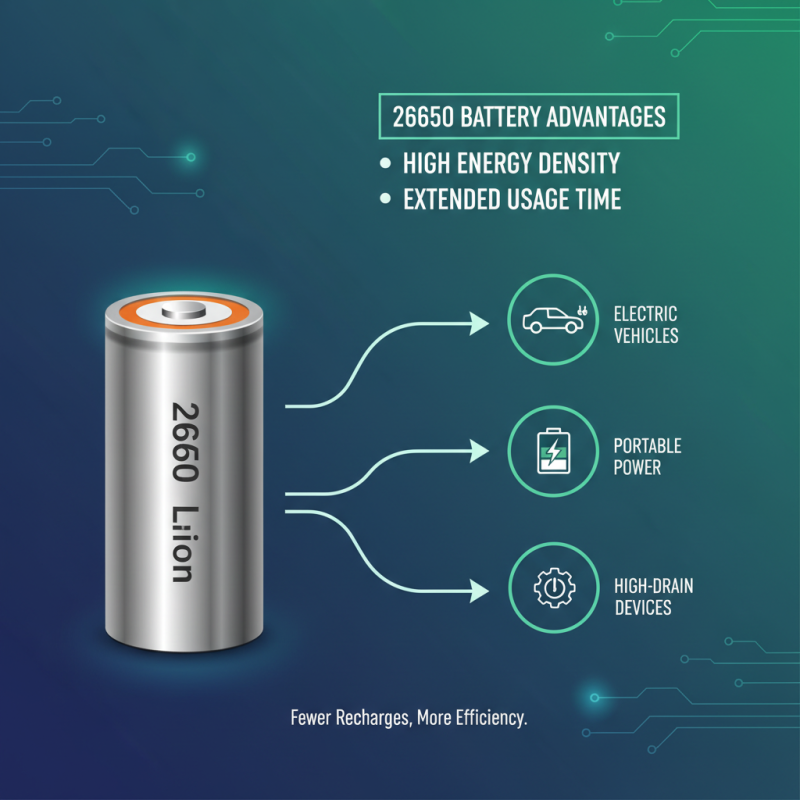

The 26650 cylindrical battery, with its robust design and ample capacity, offers numerous advantages in various applications. One of the primary benefits is its high energy density, which allows for longer usage times in devices compared to smaller battery formats. This characteristic makes the 26650 battery particularly suitable for electric vehicles, portable power sources, and high-drain applications. Users can enjoy extended operation periods without the frequent need for recharging, enhancing overall efficiency and convenience.

Additionally, the 26650 cylindrical battery exhibits excellent thermal stability and safety features. Its larger format decreases the risk of overheating and potential failures, making it a reliable choice for high-performance applications. The structural integrity of the cylindrical design also contributes to its durability, allowing it to withstand harsher conditions without compromising performance. As industries continue to prioritize sustainability and efficiency, the 26650 battery stands out as a practical option for powering innovative technologies while minimizing environmental impact.

When comparing 26650 batteries to other battery types, several key factors highlight their unique advantages. The 26650 cylindrical battery, with its larger size and capacity, typically offers a higher energy density than smaller formats such as 18650 or 14500 batteries. This means that devices requiring prolonged use can benefit from longer operational times between charges, making 26650 batteries particularly suitable for applications such as electric vehicles, power tools, and energy storage systems.

Moreover, the 26650 batteries tend to have a better thermal management system due to their size, which allows for more efficient heat dissipation. This characteristic enhances the safety and reliability of these batteries during heavy-duty operations compared to other, smaller battery types that may overheat under similar conditions. Another benefit includes their robust cycle life, which often surpasses that of smaller batteries, resulting in a longer overall lifespan. This makes 26650 batteries a compelling choice in the market, especially where performance and reliability are critical considerations.

The future of cylindrical battery production, especially in the context of 26650 battery technology, is poised for significant advancements driven by innovation and sustainability. Recent industry reports indicate that the global cylindrical battery market is expected to reach over $30 billion by 2027, growing at a CAGR of approximately 20%. This growth is largely attributed to the increasing demand for electric vehicles (EVs) and renewable energy storage solutions, which require high-performance battery systems. In particular, the introduction of automated manufacturing lines for cylindrical batteries is enhancing production efficiency and enabling higher quality control standards.

Moreover, innovations in battery chemistry and materials are likely to revolutionize the cylindrical battery landscape. Research shows that advancements in solid-state electrolytes and the use of silicon anodes can potentially increase the energy density of cylindrical batteries by up to 30%. This means that future production lines will not only focus on optimizing the manufacturing process but also on integrating cutting-edge materials that improve battery performance and lifespan. Additionally, the implementation of AI and IoT technology in monitoring production processes will lead to smarter manufacturing systems that can adapt in real time, thus reducing waste and optimizing resource use. This proactive approach to cylindrical battery production positions the industry to meet the evolving demands of energy storage and electric mobility in the coming years.