Leave Your Message

As the demand for energy storage solutions continues to rise, innovations in the 18650 Cylindrical Battery Pilot Line are shaping the future of battery technology. According to a report from the International Energy Agency, global electric vehicle sales reached 6.6 million units in 2021, highlighting the urgent need for improved battery performance. Industry expert Dr. Emily Chen notes, "The evolution of the 18650 Cylindrical Battery Pilot Line is crucial for meeting this demand."

In recent years, advancements have spurred the development of more efficient manufacturing processes. Enhanced automation and precision engineering play significant roles in productivity increases. However, achieving sustainability remains a challenge. The push for greener production methods often conflicts with rapid output demands. This complexity creates opportunities for reflection on balancing innovation with responsible practices.

Reiterating the importance of the 18650 Cylindrical Battery Pilot Line, it's evident that addressing industry issues will require thoughtful dialogue. Continuous improvement is both a goal and a necessity. Stakeholders must collaborate to navigate this dynamic landscape, ensuring that innovation serves both market needs and environmental considerations.

The 18650 cylindrical battery manufacturing sector is witnessing significant innovations. Companies are increasingly automating production lines to boost efficiency. Robots are used for tasks like assembly and quality control. This helps reduce human error and improves safety.

New materials are also making a difference. Researchers explore alternatives to traditional components. These materials can enhance battery life and energy density. However, their integration into existing lines can be complex and costly. The learning curve is steep, prompting many to rethink their strategies.

Sustainability plays a vital role in these innovations. More manufacturers are considering recycling processes within pilot lines. This shift aims to minimize waste and reduce environmental impact. Yet, achieving a fully circular system remains a challenge. Balancing performance with sustainability often leads to difficult decisions.

As we move toward 2026, the world of battery technology is evolving rapidly. New designs for cylindrical batteries promise greater efficiency and sustainability. Innovations in materials, like silicon anodes, show potential to boost energy density significantly. The shift towards eco-friendly materials could redefine production techniques. These changes might reduce environmental impact, but they come with challenges.

Battery recycling is becoming a key focus. With increased production, the need for effective recycling methods intensifies. Current systems struggle to keep pace. Enhanced recycling technologies may solve some issues, yet they also require further development. Addressing these gaps is crucial for a truly sustainable future.

Smart battery management systems are gaining traction. They enhance performance and longevity through better energy distribution. This technology could revolutionize usage patterns. However, integration remains complex and costly. Companies will need to balance advancements with practical implementation. The road ahead is filled with potential, but obstacles are present. Evaluation and adaptability will be vital as we head into this new era.

The 18650 battery sector is evolving rapidly. Key players are investing heavily in technology. New methods aim to enhance production efficiency and reduce costs. Innovations in cell design are also a hot topic. Many companies focus on improving energy density while ensuring safety.

Research and development efforts are expanding. Some manufacturers are experimenting with alternative materials. This can potentially lower dependency on conventional raw materials. However, the scalability of these innovations remains a challenge. Are these approaches truly viable in mass production?

Each leading entity faces its hurdles. Meeting environmental standards is an ongoing concern. The pressure to reduce carbon footprints is immense. Moreover, the supply chain must adapt to these changes. Collaboration among industry players might drive better solutions. Still, there’s uncertainty about how quickly this transformation will occur.

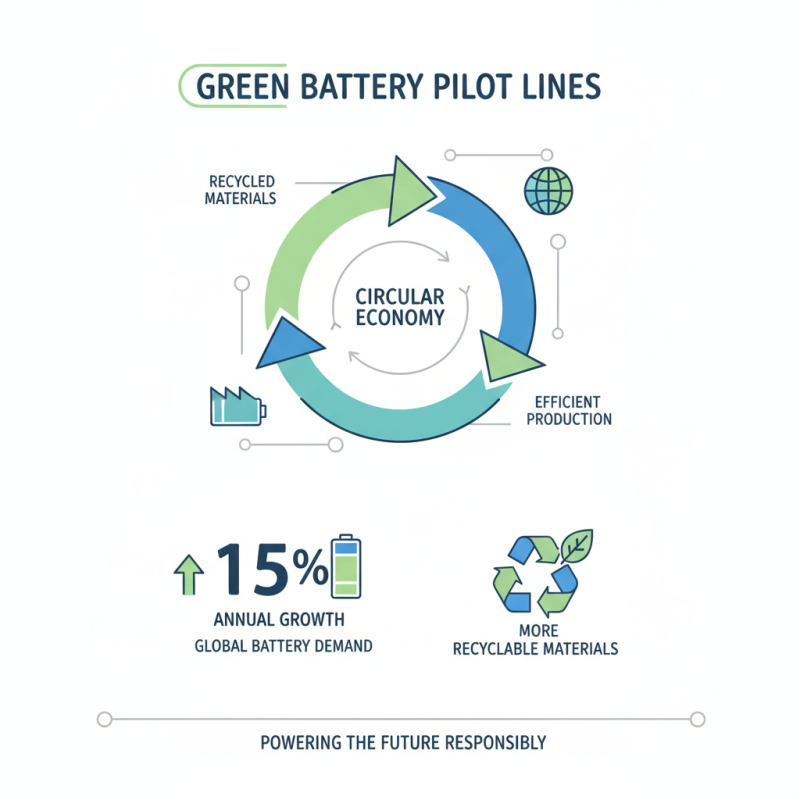

The trend towards sustainability in the development of pilot lines for 18650 cylindrical batteries is gaining momentum. According to a recent industry report, the global demand for reliable battery technology was projected to grow by 15% annually. This rising demand sparks innovation in sustainable practices. Companies are adopting the circular economy model. Materials used in battery production are more recyclable than ever before.

Numerous manufacturers are exploring ways to reduce carbon emissions. Reports indicate that around 30% of production waste can be recycled. However, implementing these practices presents challenges. Many companies face setbacks in sourcing sustainable materials. There's a need for advanced recycling technologies. Despite the ambition, the industry's overall waste management remains subpar.

Moreover, energy consumption during production processes is under scrutiny. A study noted that production facilities are still responsible for about 40% of energy usage. Optimizing energy efficiency is critical. Some pilot lines have made strides, but there's much more to achieve. As the industry progresses, attention to sustainability must not wane. Continuous reflection on these practices is essential for long-term success.

The development of 18650 cylindrical batteries faces several significant challenges. One primary issue is the demand for higher energy density. Manufacturers strive to enhance performance without compromising safety. Reaching this balance demands innovative materials and processes. Traditional materials often limit energy capacity. Newer alternatives may come with their own drawbacks, such as increased costs or reduced stability.

Another challenge is the recycling of spent batteries. Efficient recycling methods are essential for sustainability. However, current practices often yield low recovery rates. This raises concerns about environmental impact. Companies must invest in better technology to address this issue. Training workers to handle materials safely is also vital.

Lastly, scaling up production while maintaining quality is a formidable task. High-volume production leads to potential quality control issues. Inadequate oversight can result in defects. Businesses need to implement robust testing and monitoring systems. Adapting to rapid technological changes adds to this complexity. Innovations must be integrated carefully to avoid production hiccups.