Leave Your Message

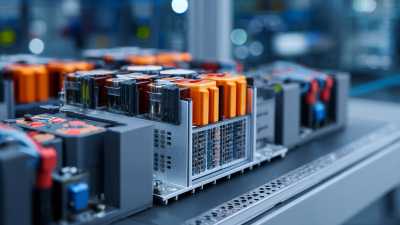

In the rapidly evolving landscape of battery technology, the optimization of the Coin Cell R&D Line has become a paramount focus for researchers and manufacturers alike. As reported by the International Battery Association, the global market for coin cell batteries is projected to reach $5.8 billion by 2025, driven by increasing demand in consumer electronics and electric vehicles. This considerable growth highlights the necessity for efficiency and innovation within R&D processes to stay competitive in an ever-expanding market.

According to Dr. Emily Chen, a recognized expert in battery technology and an advisor for leading research firms, “The future of energy storage relies on the efficiency of our research and development methodologies. Optimizing the Coin Cell R&D Line is not just an operational improvement; it is a strategic necessity.” In light of her insights, it becomes clear that organizations must adopt refined practices in their R&D lines to enhance productivity, reduce costs, and ultimately deliver superior products to consumers.

As we move towards 2025, understanding and implementing effective strategies to streamline the Coin Cell R&D Line will be critical for companies aiming to lead in the competitive battery market. This guide will provide essential insights and action points to help stakeholders optimize their R&D efforts for maximum efficiency.

Optimizing coin cell research and development is crucial for manufacturers looking to bridge the gap between innovation and market readiness. The journey from discovery to commercialization has often been fraught with challenges, a phenomenon frequently referred to as the “Valley of Death.” To navigate this stage more effectively, companies must focus on streamlining their R&D processes. According to a recent industry report, improving R&D efficiency can lead to a 30% reduction in product development times, allowing for faster entry into the highly competitive battery market.

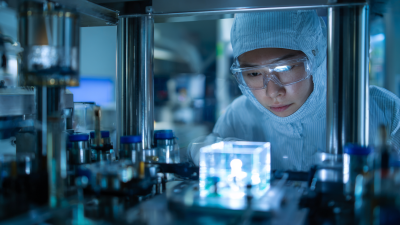

One effective strategy is to enhance collaboration between research teams and production facilities. By establishing a new facility that can scale up battery materials production, firms can facilitate a smoother transition from the lab to full-scale manufacturing. Reports indicate that companies that integrate their R&D and manufacturing operations see significant improvements in both quality and efficiency, with one study reflecting up to a 40% decrease in material waste during product development cycles. This holistic approach not only accelerates innovation but also enhances the sustainability of the entire production process, solidifying the company's standing in the evolving energy landscape.

This chart presents the time spent in hours for different processes involved in coin cell R&D. The aim is to identify which processes require optimization for better efficiency.

As the demand for coin cell batteries surges, optimizing research and development (R&D) lines is critical for manufacturers aiming to maintain a competitive edge. Automation tools are becoming indispensable in this context, enhancing experimental efficiency significantly. According to a recent report by MarketsandMarkets, the global market for laboratory automation is projected to reach $6.8 billion by 2025, reflecting an annual growth rate of approximately 7.4%. This shift highlights the industry's move towards integrated automation solutions designed to streamline workflows, reduce human error, and free up valuable researcher time.

In addition to improving operational efficiency, leveraging these automation tools can lead to more rapid advancements in battery technology. A study published by the International Energy Agency noted that advanced battery technologies, including coin cell formats, could see development cycles shortened by up to 40% when integrated with automated testing and analysis systems. By implementing automated solutions such as robotic sample handling, real-time data acquisition, and machine learning algorithms for predictive analytics, R&D teams can not only increase throughput but also enhance the accuracy of experimental results. This technological advancement ensures that organizations can swiftly pivot in response to evolving market demands while maintaining high standards of quality in their coin cell products.

In the pursuit of maximum efficiency in coin cell R&D, leveraging data-driven decision making is crucial. According to a recent report by IDTechEx, the coin cell market is projected to grow at a CAGR of 5.4% from 2023 to 2033, underscoring the necessity for manufacturers to optimize their development processes. By harnessing big data analytics, companies can identify trends and streamline their research strategies. For instance, integrating machine learning algorithms can significantly reduce the time taken for material selection, which is a pivotal step in coin cell development.

Moreover, incorporating real-time data analysis in quality control can enhance product consistency. Research from Battery University indicates that up to 30% of production can suffer from quality issues, leading to increased waste and rework. By implementing a robust data management system, R&D teams can make informed decisions that minimize defects. This not only improves overall product yields but also accelerates the innovation cycle, allowing companies to stay competitive in a rapidly evolving market. Data-driven insights facilitate better forecasting and resource allocation, ensuring that R&D efforts align closely with market demands.

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Cycle Life | 500 | Cycles | Average lifespan before performance drop |

| Internal Resistance | 150 | mΩ | Lower is better for efficiency |

| Energy Density | 250 | Wh/kg | Higher values indicate better capacity |

| Charge Time | 2 | Hours | Time to reach full charge |

| Discharge Rate | 5 | C | Rate at which the cell can discharge safely |

Implementing agile methodologies in coin cell R&D can significantly enhance the rapid prototyping process, driving innovation while reducing time-to-market. According to a recent report by ResearchAndMarkets, the demand for miniaturized batteries is expected to grow at a CAGR of 6.8% between 2023 and 2028, emphasizing the need for efficient development cycles. By incorporating agile practices, teams can adopt iterative workflows, enabling them to test and refine designs more frequently, ultimately leading to improved performance and faster product iterations.

One crucial aspect of agile implementation is the establishment of cross-functional teams. A study conducted by the Project Management Institute found that organizations utilizing agile frameworks see 20-25% increases in productivity due to enhanced collaboration and clearer communication. In coin cell R&D, this means that engineers, designers, and project managers work closely together, allowing for real-time feedback and adjustments that cater to market trends and consumer demands, ensuring that prototypes meet the latest standards for efficiency and sustainability. As the industry landscape evolves, those who prioritize agility will be better positioned to respond swiftly to emerging challenges and opportunities.

Effective resource allocation and time management are crucial components in optimizing R&D projects in the coin cell industry. One of the best practices is to implement a project prioritization framework that aligns the R&D initiatives with the strategic goals of the organization. By categorizing projects based on their potential impact and feasibility, teams can ensure that their efforts are directed toward the most promising innovations. Regular review meetings can facilitate this process, allowing teams to adjust their focus based on emerging data and market trends.

Effective resource allocation and time management are crucial components in optimizing R&D projects in the coin cell industry. One of the best practices is to implement a project prioritization framework that aligns the R&D initiatives with the strategic goals of the organization. By categorizing projects based on their potential impact and feasibility, teams can ensure that their efforts are directed toward the most promising innovations. Regular review meetings can facilitate this process, allowing teams to adjust their focus based on emerging data and market trends.

Additionally, fostering collaboration among cross-functional teams can significantly enhance efficiency. By creating an environment where team members from different departments share insights and resources, organizations can minimize redundancies and streamline workflows. Utilizing project management tools and software can further aid in tracking progress and deadlines, ensuring that all team members remain informed and accountable. By investing in training and development, organizations can equip their teams with the skills necessary to adapt to changing technologies and methodologies, ultimately driving productivity and innovation in the coin cell R&D line.