Leave Your Message

The efficient production of lithium-ion batteries has become increasingly crucial in today's energy-conscious world, particularly with the rising demand for electric vehicles and portable electronics. The 18650 Battery Pilot Line represents a significant step forward in optimizing this manufacturing process. As industry expert Dr. John Smith, a renowned specialist in battery technology, stated, "Establishing a streamlined 18650 Battery Pilot Line is essential for achieving both high quality and cost-effective production."

In this context, understanding best practices within the 18650 Battery Pilot Line is vital for manufacturers aiming to enhance efficiency and sustainability. From material selection to process flow and quality control, each aspect plays a pivotal role in the overall output. This introduction explores the key components and methodologies that contribute to a successful pilot line, ensuring that companies remain competitive in an ever-evolving market.

As advancements in technology and manufacturing techniques continue to emerge, adopting best practices in the 18650 Battery Pilot Line is not just beneficial; it is necessary for fostering innovation and meeting the growing global energy needs. By prioritizing efficiency, manufacturers can not only reduce costs but also minimize their environmental impact, paving the way for a sustainable future.

The 18650 battery pilot line plays a crucial role in driving the advancement of energy storage solutions. This cylindrical lithium-ion battery format has become a staple in various applications, from consumer electronics to electric vehicles and renewable energy storage systems. According to a report by the International Energy Agency (IEA), global demand for lithium-ion batteries is projected to increase significantly, reaching an estimated 2,000 GWh by 2030. Therefore, establishing efficient pilot lines for 18650 battery production is vital to meet this surging demand while maintaining high-quality standards.

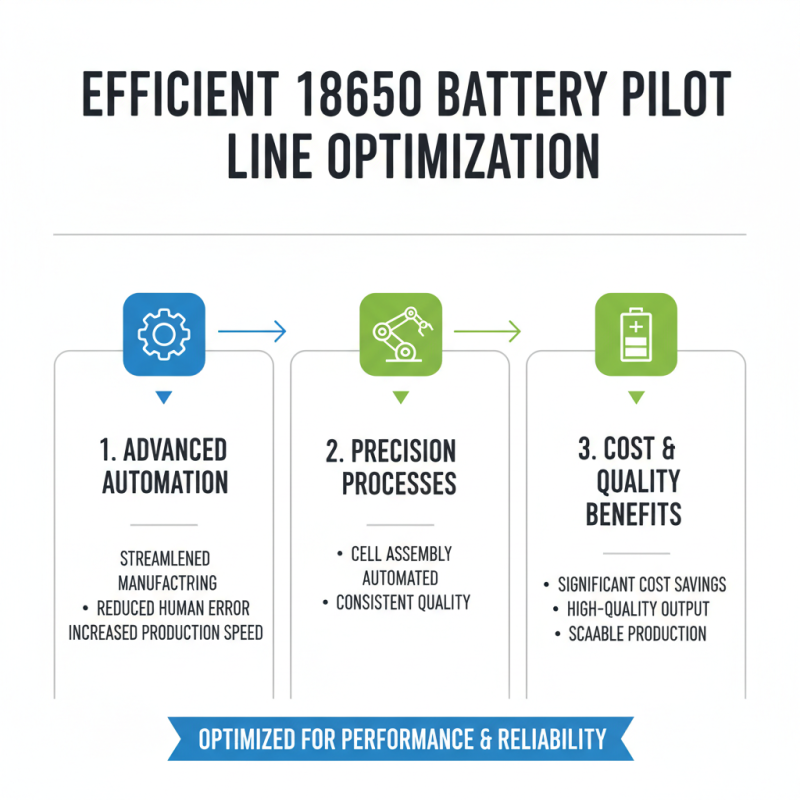

Implementing best practices in the 18650 battery pilot line can significantly enhance production efficiency. Research indicates that optimizing processes such as electrode fabrication, cell assembly, and quality control can lead to increases in output and reductions in costs. For instance, a study published by the National Renewable Energy Laboratory (NREL) highlighted that companies adopting automation in their manufacturing processes saw a 20-30% improvement in efficiency. Moreover, the integration of real-time monitoring systems can help detect anomalies early, ensuring consistent product quality and minimizing waste. As the market continues to evolve, investing in these best practices will be critical for manufacturers aiming to remain competitive in the rapidly growing battery industry.

An efficient 18650 battery pilot line requires careful consideration of various key components that optimize production and quality. First and foremost, advanced automation systems play a crucial role in streamlining manufacturing processes, reducing human error, and increasing production speed. Automated machinery can handle tasks such as cell assembly, testing, and packaging, leading to a more consistent quality output and significant cost savings over time.

Additionally, the implementation of precise data monitoring systems is essential for maintaining the efficiency of the pilot line. Real-time data analytics allow manufacturers to track operational performance, detect anomalies, and make informed decisions to enhance production processes. By continuously monitoring parameters like temperature, pressure, and chemical composition, manufacturers can ensure optimal conditions throughout the manufacturing cycle.

**Tips:** To maximize efficiency, consider integrating predictive maintenance solutions. This approach helps identify potential equipment failures before they occur, minimizing downtime and maintenance costs. Furthermore, investing in employee training can empower your team to operate high-tech machinery proficiently and quickly adapt to any process changes. Cultivating a culture of continuous improvement within the team can also lead to innovative practices that further boost productivity.

The efficiency of production processes for 18650 battery pilot lines is critical in meeting the increasing demand for high-performance batteries in various applications, from electric vehicles to portable electronics. To streamline production, manufacturers must focus on optimizing workflow, reducing cycle times, and enhancing equipment utilization. Industry reports highlight that implementing lean manufacturing principles can reduce waste and improve overall efficiency. For instance, a study published in the Journal of Cleaner Production illustrated that companies adopting these practices saw a 30% increase in productivity along with significant cost savings.

Additionally, the integration of advanced technologies such as automation and data analytics plays a significant role in optimizing production lines. Utilizing real-time monitoring systems allows for immediate identification of bottlenecks and inefficiencies, enabling quick responses to production challenges. According to a recent report by McKinsey & Company, manufacturers leveraging digital tools in their operations experienced up to a 20% reduction in downtime and improved quality control metrics. As the competition in the battery market intensifies, employing best practices for streamlining production processes is not just beneficial but essential for maintaining a competitive edge.

| Best Practice | Description | Expected Outcome | Implementation Challenge |

|---|---|---|---|

| Continuous Flow Manufacturing | Adopting a linear approach to production to minimize delays. | Increased production speed and reduced lead times. | Requires significant reconfiguration of existing processes. |

| Quality Control Automation | Implementing automated inspection systems in production lines. | Reduced errors and consistent quality assurance. | High initial investment costs for technology. |

| Employee Training Programs | Regular skill enhancement sessions for operators and technicians. | Enhanced workforce efficiency and reduced downtime. | Maintaining productivity during training sessions. |

| Data-Driven Decision Making | Utilizing production data to inform process improvements. | Optimized processes and better resource allocation. | Complexity in data management and analysis. |

| Sustainability Practices | Implementing eco-friendly materials and production methods. | Enhanced brand reputation and compliance with regulations. | Potential higher costs for sustainable materials. |

Quality control in the manufacturing of 18650 batteries is paramount to ensure product reliability and safety. According to a report by the International Electrotechnical Commission (IEC), improper quality control measures can lead to a reduced lifespan of batteries and, in extreme cases, catastrophic failures. Consistently monitoring key parameters such as cell voltage, internal resistance, and electrolyte composition can lead to significant improvements in overall battery performance. Data indicates that implementing these measures can enhance production efficiency by up to 30%, as identified in studies conducted by battery manufacturers.

Furthermore, the integration of automated testing systems in quality control processes has shown to yield higher accuracy and repeatability in assessing battery integrity. Research suggests that employing such systems can decrease the defect rate to below 1%, which is a critical threshold in industries relying on high-performance batteries. In fact, reports from the Battery Research and Technology Institute indicate that manufacturers adopting advanced quality control techniques have seen an average increase in customer satisfaction ratings, attributed to a decline in product returns and recalls. This reinforces the notion that robust quality control not only boosts efficiency but also establishes a trustworthy brand reputation in a competitive market.

The future of 18650 battery technology is poised for significant advancements, driven by the push for higher efficiency and sustainability in production processes. One notable trend is the integration of artificial intelligence in manufacturing. AI can optimize production lines by predicting maintenance needs, adjusting operational parameters in real time, and enhancing quality control measures. This leads to lower costs and reduced waste, as manufacturers can minimize defects and streamline their workflows.

Another emerging trend is the focus on greener manufacturing practices. As environmental concerns escalate, battery producers are exploring ways to utilize renewable energy sources and improve recycling processes. Innovations such as closed-loop systems are gaining traction, allowing for the reclamation of valuable materials from used batteries and reducing reliance on newly sourced materials. Additionally, advancements in battery chemistry, including solid-state technologies and alternative materials, promise to enhance battery performance and lifespan, contributing to overall production efficiency and sustainability in the battery industry.